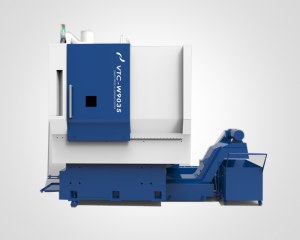

UNIVERSAL HORIZONTAL LATHE

The machine tool adopts the mainstream oblique bed structure of Europe, America, and Japan, with integrated electromechanical, hydraulic, and gas design, compact structure, and strong operability. The sheet metal adopts a fully enclosed protective structure with good chip removal, drainage, and leakage effect.

FEATURES OF UNIVERSAL HORIZONTAL LATHE

The mineral-cast rectangular hard rail bed has good shock resistance, low thermal sensitivity coefficient, and good overall rigidity.

The mineral casting spindle box has low vibration, high speed, and high efficiency, which is about 30% higher than the market average efficiency.

According to industry requirements, imported spindle units are specially ordered.

The chip conveyor is separated from the water tank, making cleaning and maintenance more convenient.

The main processing objects are the rough and fine turning of the common 12-22 inch passenger wheel hubs and the car's wheel hubs, it can also be used for the turning of similar disc parts.

WORKING PRINCIPLE OF UNIVERSAL HORIZONTAL LATHE

The working principle of the cnc lathe machine turning: The main function of the braking device of the CNC horizontal lathe is to be used in the parking process of the lathe, to overcome the rotational inertia of the moving parts in the headstock, to control the spindle to quickly stop rotating to shorten the auxiliary time and thus to horizontal The purpose of the lathe to install the brake.

As one of cnc machining center manufacturers , DEED has a complete set of independent research and development production equipment and technology and has obtained many national patents at present.

UNIVERSAL HORIZONTAL LATHE SPECIFICATION

HP800-WC

|

Feed |

Max. turning diameter |

φ850 |

|

Max. the cutting diameter of the hub |

22" |

|

|

Max. cutting Length of the hub |

12" |

|

|

X-axis travel |

﹣30~370 |

|

|

Z-axis travel |

850 |

|

|

X/Z axis rapid traverse feed |

20/20 |

|

|

Spindle |

Spindle speed |

2500 |

|

spindle motor power |

30/37 |

|

|

spindle torque |

375 |

|

|

spindle nose specification |

A2-8 |

|

|

spindle diameter |

φ160 |

|

|

ATC |

tool station |

8 |

|

inner tool diameter size |

φ50 |

|

|

Max. outer tool holder diameter |

32*32 |

|

|

adjacent tool change time |

0.6 |

|

|

screw |

X-axis |

φ50*P10 |

|

Z-axis |

φ50*P10 |

|

|

Accuracy |

positioning X |

0.008 |

|

positioning Z |

0.008 |

|

|

Repeatability X |

0.006 |

|

|

Repeatability Z |

0.006 |

|

|

Others |

X/Z axis servo motor power |

4/4 |

|

X/Z axis servo motor torque |

22/22 |

|

|

X/Z axis servo motor max. speed |

3000 |

|

|

cooling water tank capacity |

600 |

|

|

Size |

4169*2150*2147 |

|

|

Weight |

11 |

|

|

control system |

FANUC 0i-TF |

Contact : chinetool deedma, 0537 3451030

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of UNIVERSAL HORIZONTAL LATHE Search in a category : Stock lots Search in a category : horizontal, universal, lathe |

Wednesday, September 14, 2016

Quantity : 5000 - Price : 100,00 €

Bellows Seal Stop Valves (Angle Type) DIN Angle Type Bellows Sealed Stop Valve DIN Bellows Seal Globe Valve DIN Faltenbalgventil Eckform DIN Válvulas de fuelle(Paso angular.) DIN ventil uzavírací s vlnovcem rohový DIN Standard seteventil med belg (Vinkel modell) DIN Standardında...

ETM Armaturen

- 59590 - Henri Durre

- 86 577 67953935

Wednesday, September 14, 2016

Quantity : 5000 - Price : 50,00 €

Long life-Heavy Duty Bellows Seal Stop Valves DIN Standard Long Life-Heavy Duty Bellows Sealed Stop Valves DIN Long life bellows Seal Stop Valve DIN Long life bellows globe valve DIN Long bonnet bellows globe valve DIN Faltenbalgventil lange Bauform DIN Válvulas de fuelle de...

ETM Armaturen

- 59590 - Henri Durre

- 86 577 67953935

Monday, July 20, 2015

Maroc vente fournisseurs, tissus technique, tapis isolation acoustique, grossistes, producteurs, import-export Société italienne spécialisée en production de tissus techniques pour construction et travaux publics cherche importateur exclusif au Maroc pour tapis isolation acoustique...

impresa in marocco sarl

- 20000 - CASABLANCA

- 06 29 90 85 75