STANDING SEAM ROLL FORMING MACHINE

With the gradual increase of cold rolling capacity, the consumption of rolls (including work rolls, support rolls and intermediate rolls, etc.) and oil film bearings is also increasing. In this case, more and more demands are placed on the rolls. It is necessary to transform the roll production management to meet the needs of fast-paced and high-capacity. Standing Seam Roll Forming Machine can produce more high quality rolls to meet these needs

1. Roll production management system function

The roll production management system functions mainly include subsystem management, assembly management, plan management, grinder fault management, location management, report management, and communication management. Its core composition is standing seam roll former. The component management mainly undertakes the management functions of the rolls, bearings, bearing housings and the like in the grinding roll room. And the standing seam roll forming machine has high speed rolling shafts and can produce rolls efficiently.

Starting from the new roll into the factory, after each rolling of the unit, grinding to the grinding machine and rolling to the standing seam roll forming machine, until the roll is scrapped, the whole process tracking management of the roll is carried out. The assembly management consists of two parts: roll, bearing, bearing box assembly management and roll matching management, which provides proper distribution information for the production of the unit to meet the needs of the production roll.

2. Demand analysis of roll production management system

The position management of the roll production management system divides and defines the roll stacking area in the roll shop according to the roll work type, which is convenient for the operator to lift the roll. Report management provides users with the means to master the working conditions between the rollers. Interface management mainly develops the corresponding interface with external systems and designs its content and format. besides, it is very important to have a good standing seam roll forming machine in the roll production management system.

On this basis, the information exchange between computer systems is realized, and the organic connection and cooperative operation between different information systems are achieved. The main systems that interact with the grinding roll management system include the rolling line L2 system, the control system for the internal grinding machine between the rolls, and the like. Communication management mainly manages the underlying communication functions between the roll-to-roll management system and other computer systems, thereby enabling data interaction between systems.

Develop corresponding application receiving programs and maintenance functions, and establish corresponding telegram sub-tables for all interactive telegrams.

BOSJ is a professional china roll forming machine manufacturer,we provides china roll former, guardrail forming machine, standing seam roll former for sale, roll former for sale and etc. Want to know more? Please contact us.

Contact : Wang Joyce , 0510 86062268

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of STANDING SEAM ROLL FORMING MACHINE Search in a category : B2B Services Search in a category : forming, roll, machine, standing, seam |

Thursday, March 07, 2013

Quantity : 10 - Price : 800,00 €

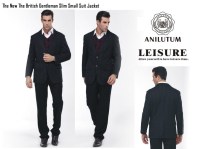

Origin China Model Number R206100 Brand Name Anilutum Gender Men's Material Polyester Season Winter Type Business Suit Brand Anilutum The New The British Gentleman Slim Small Suit Jacket Brand: Anilutum Style: Fashion Type: Men's Suit Online: 9AP-5PM Aoniludan...

H&Y International Fashion Limited

- anilutum

- EC1V 2NX - London

- +86 13724036041

Friday, March 08, 2013

Quantity : 10 - Price : 80,00 €

Origin: China Model Number: V211141 Brand Name: Anilutum Feature: Gender: Men's Material: Style: long-sleeved shirt Online: 9AP-5PM Anilutum Brand Slim Solid Color Long-sleeved Shirt V211141 Aoniludan Anilutum for the British men's top business brand in 2003 from Guangzhou Ming...

H&Y International Fashion Limited

- anilutum

- EC1V 2NX - London

- +86 13724036041

Wednesday, March 23, 2016

Quantity : 200 - Price : FOB Keelung, Taiwan

No Matter you looking for a beauty care or healthcare product, our Bubble Bath Spa Massager have a fully functions to meet your any request. You might be curious that what the function of spa massager it is?! Merits of MSW-104 are as follows; 1. Based on the principle of explosion...

LienJie International Ltd.

- 414 - Taichung City

- +886 4 23367128