Solar Photovoltaic Support Rolling Machine

SOLAR PHOTOVOLTAIC SUPPORT ROLLING MACHINE

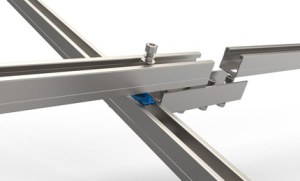

Double-in-roll c-shaped steel photovoltaic bracket is mainly applicable to the ground photovoltaic power station and concrete flat-roof photovoltaic power station. The bracket has a strong adjustable ability, high structural strength, beautiful shape, standard bending angle, accurate hole position, straight angle, accurate size, complete specifications, and economical price, which can meet most of the needs of customers. Double-in-roll c-shaped steel is a special C profile steel. It can also be used for kinds of shelves, ceiling frames, drywall partition, steel structure building, and so on. The series of Hangzhou Roll Forming Technology's solar PV support solar making machine can produce double-in-roll c-shaped steel photovoltaic brackets with consistently high quality at a stable speed.

Features and Advantages of Solar Photovoltaic Support Rolling Machine

Support roll forming for both heavy and light-duty use

Adopt changing spacers to make multi sizes profiles sections

Integrate inline flexible punching system

Pre-cutting and Post cutting is optional

Forming speed around 12-15 m/min

Multi-Patents under both CE Certified, EUROPEAN quality standards

Ready machines in stock for prompt delivery.

Suitable Coil Sheet Material for Solar Panel Rack Forming Machine

Suitable material: Cold/hot Rolled Steel, Galvanized Steel

Thickness: 1.5-3.0(mm)

Yield Strength: 230-300 (MPa)

Width: as profile requests

Technical Parameters of Double Inner Coil C-shaped Steel Photovoltaic Support

|

Installation location |

ground or flat concrete roof |

|

Main material |

hot dip galvanized carbon steel |

|

Design wind pressure |

0.55kN/m ^ 2 |

|

Design snow pressure |

0.5kN/m squared |

|

Service life |

30 years |

Production Line Components and Parameters of Solar Panel Rack Forming Machine

|

1. Decoiler |

3t/5t Motor/hydraulic motor/passive (optional) |

|

2. Feeding table |

|

|

3. Leveling device |

|

|

4. Holes punching device |

as profile requests |

|

5. Roll forming system |

12-15m/min |

|

6. Safety cover |

optional |

|

7. Post cutting device |

|

|

8. Output System |

Manual supporter/ Automatic Stacker (optional) |

|

Stackmaster |

(Output direction) Lateral/Longitudinal (optional) |

|

9. Hydraulic system |

Power supply for holes punching /post-cutting system |

|

10. Electric control system |

MITSUBISH/ SIEMENSE/AMS (optional or as requested ) |

Working Flow of Solar Panel Rack Forming Machine

Pre-cutting flow:

Decoiler (passive/auto) → Feeding and Guiding Table →leveling system → hole punching system (as profile requests) → pre-cutting to length → Roll Forming System → Output Manual Supporter/Auto Stacker(optional)

Post-cutting flow:

Decoiler (passive/auto) → Feeding and Guiding Table →leveling system → hole punching system (as profile requests) → Roll Forming System → Post-Cutting to length (Hydraulic) → Output Manual Supporter/Auto Stacker(optional)

If you need any kinds of tube mill equipment, please contact us, as a professional metal machine manufacturer, RF is willing to offer you high quality products.

Contact : liu Tyler, +86 571 82686709

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Solar Photovoltaic Support Rolling Machine Search in a category : Vehicles Search in a category : solar, photovoltaic, rolling, machine, support |

Sunday, February 26, 2017

Quantity : 500 - Price : 12,00 €

♦ Functions * 1-channel temperature monitor * 2-channel fan speed control * 4-level fan speed control (manual) * Fan speed storage function * Immediate visual indication of Fan operation ♦ Buttons * POWER: Turn off the system power * UP: Increases fan speed ( level 1–...)

Tengda Electronics Limited

- simeongao

- 518102 - hongkong

- +85 2 21 10 18 65

Tuesday, March 03, 2026

Quantity : Customers - Price : Negotiable

Cuticle Pushers and Cleaners are designed to push the cuticles away from the nails and clean the nail surface without scratching or harming the cuticle.There are variety of Cuticle Pushers & Cleaners for both fingernails and toenails. Cuticle Pushers with Curved end are easy...

Aerona Beauty manufacturers of beauty care instruments

- aeronabeauty

- 51310 - Sialkot

- 923217106500

Friday, February 12, 2016

We are a company specializing in agricultural production, with the 2016 campaign of a major production of cashew nuts estimated at 20,000 tons. Given the rampant growth of our production, we are looking urgently serious buyers for a long-term win-win partnership to ensure the flow...

Société

- 00229 - Parakou

- +22 9 62 82 37 99