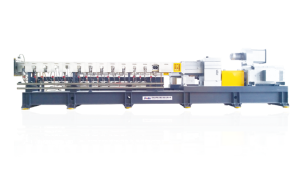

Plastic Compounding Machine

The twin-screw extruder is composed of a transmission device, a feeding device, a barrel, and a screw, and the functions of each component are similar to single-screw extruder. The difference from the single-screw extruder is that there are two parallel screws in the twin-screw extruder.

The complex flow pattern of the material in the twin screw compounding machine macroscopically shows the advantages that the single-screw extruder cannot match, for example, sufficient mixing, good heat transfer, large melting ability, strong exhaust ability and good temperature control of the material, etc.

Description About Plastic Compounding Machine

|

Item |

Description |

|

Place of origin |

China |

|

Brand name |

JWELL |

|

Model number |

CJWH-85 |

|

Capacity |

300-500kg/hr |

|

Typical application |

TPU |

|

Packaging details |

Wooden pallet packing |

|

Delivery time |

90days |

|

Payment terms |

TT. LC |

Specifications of Plastic Compounding Machine

|

Model |

Diameter |

L/D |

Screw speed |

Motor Power |

Torque per shaft |

Specific torque |

Capacity Range |

|

mm |

rpm/min |

KW |

N.m |

T/A3 |

kg/hr |

||

|

CJWH35 |

35.6 |

24~68 |

600 |

30 |

235 |

8.7 |

75~150 |

|

1000 |

45 |

8.7 |

110~220 |

||||

|

CJWH40 |

41.1 |

24~68 |

600 |

45 |

357 |

8.7 |

110~220 |

|

1000 |

75 |

8.7 |

190~380 |

||||

|

CJWH52 |

51.4 |

24~68 |

600 |

90 |

692 |

8.7 |

220~440 |

|

900 |

132 |

8.7 |

330~660 |

||||

|

CJWH65 |

62.4 |

24~68 |

600 |

160 |

1224 |

8.7 |

400~800 |

|

900 |

220 |

8.7 |

550~1100 |

||||

|

CJWH75 |

71 |

24~68 |

600 |

220 |

1880 |

8.7 |

550~1100 |

|

800 |

315 |

8.7 |

800~1600 |

||||

|

CJWH85 |

81 |

24~68 |

600 |

315 |

2713 |

8.7 |

800~1600 |

|

800 |

450 |

8.7 |

1100~2200 |

||||

|

CJWH95 |

93 |

24~68 |

600 |

500 |

4131 |

8.7 |

1250~2500 |

|

700 |

600 |

8.7 |

1500~3000 |

||||

|

CJWH110 |

108 |

24~68 |

500 |

630 |

6346 |

8.7 |

1500~3000 |

|

600 |

800 |

8.7 |

2000~4000 |

||||

|

CJWH120 |

120 |

24~68 |

500 |

900 |

8705 |

8.7 |

2250~4500 |

|

600 |

1000 |

8.7 |

2500~5000 |

||||

|

CJWH135 |

132 |

24~68 |

400 |

900 |

11586 |

8.7 |

2250~4500 |

|

500 |

1000 |

8.7 |

3000~6000 |

Plastic Compounding Machine Application

Petrochemical Powder Pelletizing and Powder Compouding:

Petrochemical powder pelletization and powder modification are one of the most important applications for twin screw extrusion machine. Through continuous efforts, optimization, and improvement, the integration of industry resources has been widely recognized by the market.

Bio-degradable Plastic Compouding and Pelletizing Series:

Typical application as plastic alloy, starch filled compound, bio-mass filled compound or mineral power filled compound for bio degradable plastics as PLA, PBAT, PBS, PPC, PCL, TPS, and PHA, etc.

Plastic compounder machine Performance and Advantages

The screw and barrel adopt the "building block" structure, which has good interchangeability, and can be used in any combination according to the different material processing technology;

The cylinder body is made of nitrided steel and bimetal materials, which are wear-resistant and corrosion-resistant, and extend the service life; the threaded elements are made of nitrided steel and high-speed steel. Normal tooth surface clearance, and good self-cleaning;

The specially designed connection method and transmission device enhance the strength of the threaded element and the mandrel. The above measures achieve the purpose of uniform material dispersion, good mixing and plasticizing effect, short material retention time, and high conveying efficiency.

JWELL Extrusion Machinery Co. Ltd is a high-tech manufacturer specializing in the research and development of yarn spinning machines, we provide polyester yarn making machine, jwell extruder, plastic profile extrusion, compounding machine. Contact us to know more.

Contact : Sun Mac, 86 0519 87878918

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Plastic Compounding Machine Search in a category : B2B Services Search in a category : machine, compounding, plastic |

Thursday, April 09, 2015

Quantity : 100 grams - Price : 10USD

RTV Silicone Rubber Applications: RTV Silicone Rubber is great to make poly resin crafts, PU crafts, PU resin crafts, gypsum crafts, u nsaturated resin crafts, lighting and candles crafts, plastic toy, stationery gifts crafts industry, RTV Silicone Rubber Advantages: light viscosity...

Guangzhou OTT New Materials Co.,Ltd.

- 510800 - Guangzhou

- 86 020 86819712

Tuesday, February 17, 2026

Quantity : 10.000 - Price : 1500 a 1600$mt

We are able to supply the best quality frozen food products worldwide. Our prices are very competitive and are the best you can find. We spend our time in understanding our customers need and we have the skills and ability to meet every customer's specific requirement. With a skill...

IRAN Trade

- ogfrance

- 93201 - Tehran

- +33 7 62 58 79 19

Monday, March 04, 2013

Quantity : 30 - Price : $425.00

Samsung Galaxy Note II It's a phablet… phone cum tablet. The Note II is an ultimate Smartphone with the latest features and specifications to enthrall any tech savvy person. Specifications: Basic Information Model N7100 2G:GSM 850/900/1800/1900 3G:WCDMA 850/900/1900/2100MHz Sim Card...