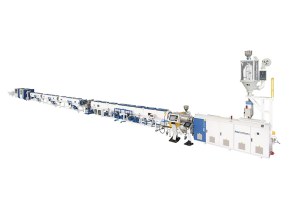

Pipe Extrusion Line

As a pipe extrusion line supplier, Jwell offers different types pipe extrusion machine to meet production for various with different applications, such as PVC pipe, HDPE pipe, PP-R pipe, RTP pipe, PLA degradable straw, Electrical conduit pipe, Corrugated pipe, Steel reinforced spiral pipe, Silicon core pipe, Medical tube, Hollow pipe, Threading pipe, Communication pipe, Multilayer pipe and Technical pipe, etc.

All series china plastic extrusion lines adopt high-efficient extruder to ensure higher output, better plasticizing, lower energy consumption and stable production. Based on Jwell special screw structure and advanced extrusion technology, our high quality pipe extrusion machines are suitable for processing many different polymers to meet customers requirements.

We choose Intelligent SIEMENS PLC control system, ABB inverter, high-end transmission system and precision electrical components, which can highly improve the equipment performance and make the operation process very easy.

Pipe Extrusion Line Lists

PVC Pipe Extrusion Line

UPVC CPVC Water Supply Drainage Pipe Extrusion Line

PVC Electrical Conduit Pipe Extrusion Line

PVC Silent Water Drainage Pipe Extrusion Line

PVC Double-cavity/Four-cavity Pipe Extrusion Line

Three-Layer PVC Pipe Co-extrusion Line

PVC Communication Threading Pipe Extrusion Line

PVC Medical Tube Extrusion Line

PVC Hollow Winding Pipe Extrusion Line

HDPE Pipe Extrusion Line

Large Diameter 800-2000mm HDPE Water Gas Supply Pipe Extrusion Line

High Quality 63-630mm PE Pipe Extrusion Line

PE Steel Reinforced Spiral Pipe Extrusion Line

PE Insulation Pipe Extrusion Line

High Speed and Energy Saving HDPE Pipe Extrusion Line

Multi-layer HDPE Solid Wall Pipe Co-extrusion Line

MPP PE Electrical Conduit Pipe Extrusion Line

PE, PP, ABS Film Roll Core Tube Extrusion Line

Corrugated Pipe Extrusion Line

Horizontal Double Wall Corrugated Pipe Extrusion Line

Vertical Double Wall Corrugated Pipe Extrusion Line

Special Plastic Pipe Extrusion Line

PP-R, PE-RT, PE-X Cool & Hot Water Small Pipe Extrusion Line

High Pressure RTP Twisted Composite Pipe Extrusion Line

Silicon Core Pipe Extrusion Line

3D Printer Filament Extrusion Line

PLA Biodegradable Straw Extrusion Line

Fiber Glass PPR Pipe Co-extrusion Line

PP Pipe Extrusion Line

Why Choose Jwell As Pipe Extrusion Line Supplier

Jwell Pipe Extrusion Machine

As an established plastic pipe extruder manufacturer, we are a 25-year manufacturing vendor with vertical set-up, which means we have a great control of supply chain and we are cost-effective. There're over 3000 employees working at Jwell so that we can offer reliable, professional and sustainable service for customers at any time. Jwell has specialized in plastic extrusion technology for over 25 years with rich experience, driving plastic extrusion industry keep forward. Jwell extruder has the advantages of good melt homogeneity, better plasticization, higher output and long service time.

Common Pipe Extrusion Machine

Most manufacturers often change component suppliers or take much time to order spare parts. They adopt outdated technical specification for extrusion machine without reducing energy consumption or improve production capacity. Many our customers who used these old machines said although the price of the extrusion pipe machine is very low, they cannot be used for a long time. Also, some extruder line suppliers can't offer reliable service, because they don't have enough resource to support it.

Factors Affecting Extrusion Machine Production

Screw structure

Different screw structures directly affect the plasticization of plastic raw materials and the quality and output of final products.

Transmission system

Provide the screw with appropriate speed range, stable speed and uniform torque, and be able to withstand the huge screw axial force generated in the production process.

Electronic control system

Great electronic control system can ensure smooth production and affects performance of heating, cooling and pressure system.

Heating and Cooling system

Accurate and uniform heating and cooling system play an important role in screw extrusion and calibration, then affects thickness and surface of final products.

What is Pipe Extrusion Process?

There are six steps during pipe extrusion process. Firstly, mix material, then extrusion part, pipe calibration, cooling, haul off, cutting. The following are the causes and solutions of some problems during pipe production process.

Insufficient cooling: It is necessary to increase the water inlet of the sizing sleeve or increase the spacing between the die and the sizing sleeve.

Contact : com JWELL, 0519 87836658

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Pipe Extrusion Line Search in a category : Raw materials Search in a category : pipe, extrusion |

Friday, December 15, 2017

OEM PART NO DESCRİPİTİON 66072 Crown Wheel and Pinion FOR CARRARO 13X30 66941 Crown Wheel and Pinion 15x37 2277448 CATERPİLLAR AİR FİLTER OUTER 2277449 CATERPİLLAR AİR FİLTER İNNER 01/117901 FAN BELT 01/124403 FAN BELT 01/124404 02/100073 Oil Filter Canister Type, MEDİUM MODEL 02/100284...

ANAC MAKINA CO LTD STI

- 34800 - İSTANBUL

- +905069691531

- +9005069691531

Wednesday, September 25, 2013

Quantity : 88999 - Price : 5 223,00 €

Hebei Hualun Wire & Cable Co., Ltd is one of the manufactures of wire and cable in China. It is the professional modernized enterprise for producing, researching and developing and selling high and new products of wire and cable. The company is located in Xingbieying Industrial...

hebei hualun wire&cable co ltd

- 062461 - hejan

- 00863173893456

Saturday, August 20, 2016

Quantity : MOQ:1piece - Price : $145/meter

FOB Price: US $168 - 180 / Meter | Get Latest Price Min.Order Quantity: 2 Meter/Meters Supply Ability: 10 Unit/Units per Week Port: Huangpu, Shenzhen Payment Terms: L/C,T/T,Western Union Quick Details Plant Type: Trees Material: Fiberglass Place of Origin: Guangdong...

Songtao Artificial Tree Co., Ltd.

- 510000 - Baiyun District

- 86 18898642060