Palm oil refining machine and fractionation machine for sale

Quantity : 1 Price : 30 000,00 €

1-10tpd batch type palm oil refining machine

Generally speaking, after we press palm fruit, we will get the crude palm oil. Due to there are still some impurities such as phospholipids, FFA, pigment, odor, etc. in the crude oil, and these impurities will directly change the oil's color, smell, taste, transparency, stability degree and nutrition, which not only affect the price of edible oil, but also make the oil easy to deteriorate when storing. So we need to use palm oil refining machine to refine the crude palm oil to get high quality cooking oil.

Small scale palm oil refining machine

Small scale palm oil refining machine

Depending on the different of customer's requirements and production scale, there are three different types of palm oil refining machine can be chose to produce cooking oil, they are: batch type palm oil refining machine, semi-continuous palm oil refining machine and fully continuous palm oil refining machine. Today we mainly introduce 1-10tpd batch type palm oil refining machine. (Related post: What is the price of palm oil refining machine?)

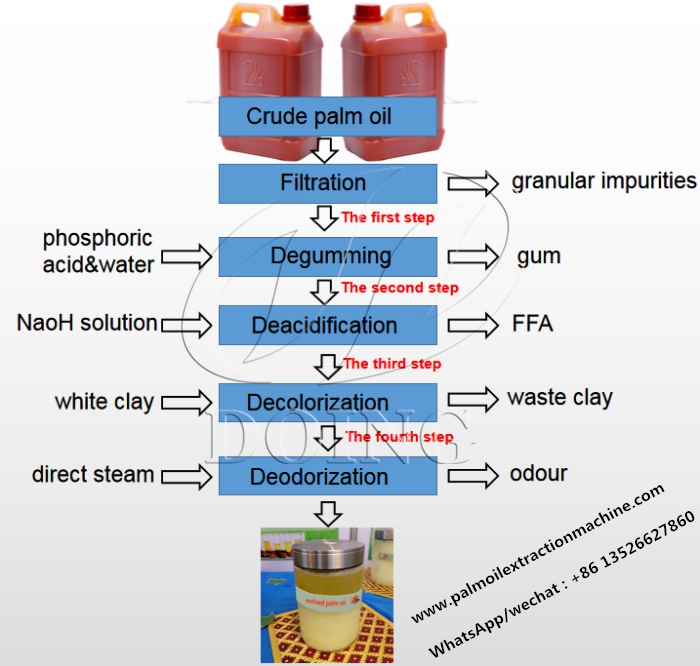

As with continuous palm oil refining machine, 1-10tpd batch type palm oil refining machine also includes four mainly processes: degumming, deacidification, decolorization, deodorization. Here, Henan Glory Oils & Fats Engineering Co., Ltd will take you learn about each refining process of batch type palm oil refining machine.

Palm oil refining process flow chart:

Palm oil refining process flow chart

Palm oil refining process flow chart

Degumming section: There are some phospholipid, gum, and protein, they can be dissolved into oil when there is no water, but once there is water in oil, these impurity can be dissolved into water. So, in degumming section, we usually use the hot water to wash crude oil for two-three times to make gold phospholipid condenses and reduces colloid, To reach the better dugumming effect, we usually need wait several hours,then open the below valve release the gums.

Deacidification section: During this section, The most widely used method is adding some chemical materials (alkali liquor) to remove the acid materials. And then open the below valve release the soapstock.

If the content of FFA in crude oil is high, we will lost much oil and get much soapstock. But if the content of FFA in crude palm oil is low, we will get more oil and less soapstock.

Decolorization section: Decolorization is carried out by the obsorption function of white clay, this step usually need 25mins, temperature requirements around 105-110 Celsius.

Deodorization section: This step have high temperature requirement , around 260 Celsius, based on very high temperature, steam can remove oxidation number, aldehydes, and ketones in crude oil. In addition, some of acid and bad smell also can be taken off in this step..

After the above four step, we will get the RBD palm oil, if you want to further process RBD palm oil to get palm olein and stearine, we can also supply the palm oil fractionation plant.

Photos of batch type palm oil refining machine:

Palm oil refining equipment with various processing capacity

Palm oil refining equipment with various processing capacity

Do you want to set up a palm oil refinery plant? Welcome to contact Henan Glory Oils & Fats Engineering Co., Ltd, we will customize the palm oil refinery process and solution for each of customer depending on their specific situation and needs.

Contact : Wendy Wang, +86 371 56771823

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Palm oil refining machine and fractionation machine for sale Search in a category : B2B Services Search in a category : palm, machine, refining, fractionation, sale |

Tuesday, December 23, 2025

Quantity : 80000 Ream - Price : $0.79/Ream for 8000

SPECIFICATION - Sheet Size: 210mm x 297mm/297mm x 420mm International Paper Standards Size(ISO) A4/A3 - Quality: Imported 100% Virgin Wood Pulp - Whiteness: 102-104%,Natural White - Grading: A - Thickness: 106cm - Capability: High Speed Copying 100ppm, Laser Capable,Inkjet Capable...

NATH LAOH LTD

- 50100 - Chiang Mai

- +66 9 95 35 59 56

Saturday, July 18, 2015

Especificaciones: Tamaño de hoja: 210mm x 297mm, Internacional A4 Calidad: 100% importado de pulpa de madera virgen Blancura = 102-104%, blanco natural Capacidad: Copying100ppm alta velocidad, Laser Capaz, Especificaciones de chorro: Tamaño de hoja: 210mm x 297mm, Internacional A4 Calidad...

PAPERY (THAILAND )CO LTD

- 10400 - Bangkok

- 098765443533

Thursday, September 28, 2017

Quantity : as per ite - Price : based on Qty

Dear Sir, We deal with Building Materials & Machine Spares since 1987 and LED Lighting and Solar Products since 2014. Our Product Range : Structural Steel : MS Angles, Channel, Beams, Flat Bar, Plain sheets, Chequered plates,Round Bars. Aluminum: plain sheets, Angles, Flat Bars...

Rashid Essa Building Material Co. LLC

- sajj

- 971 - dubai

- 04 2563282

- 971 55 6995965