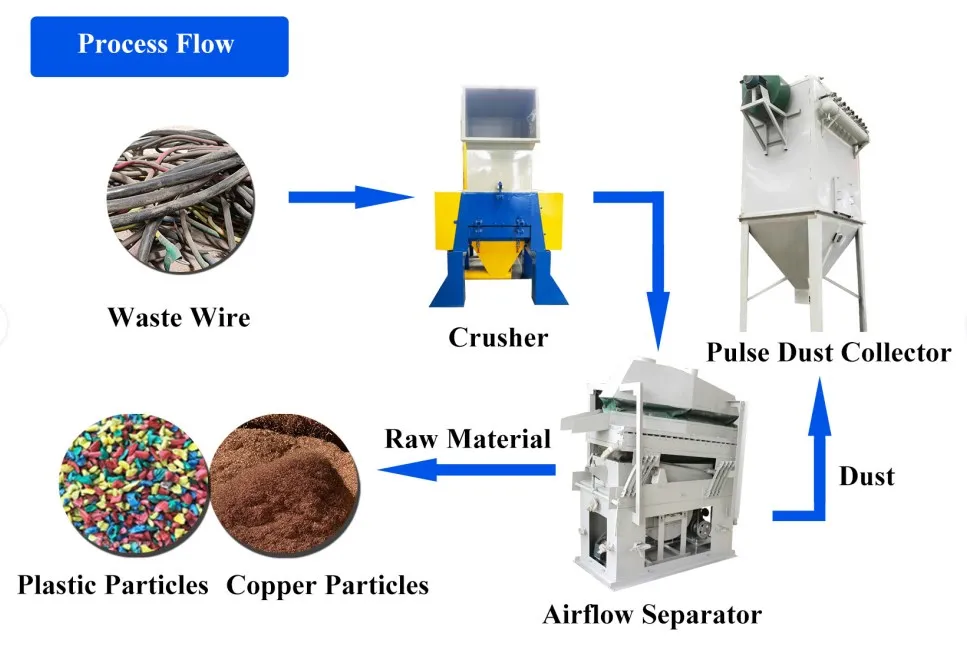

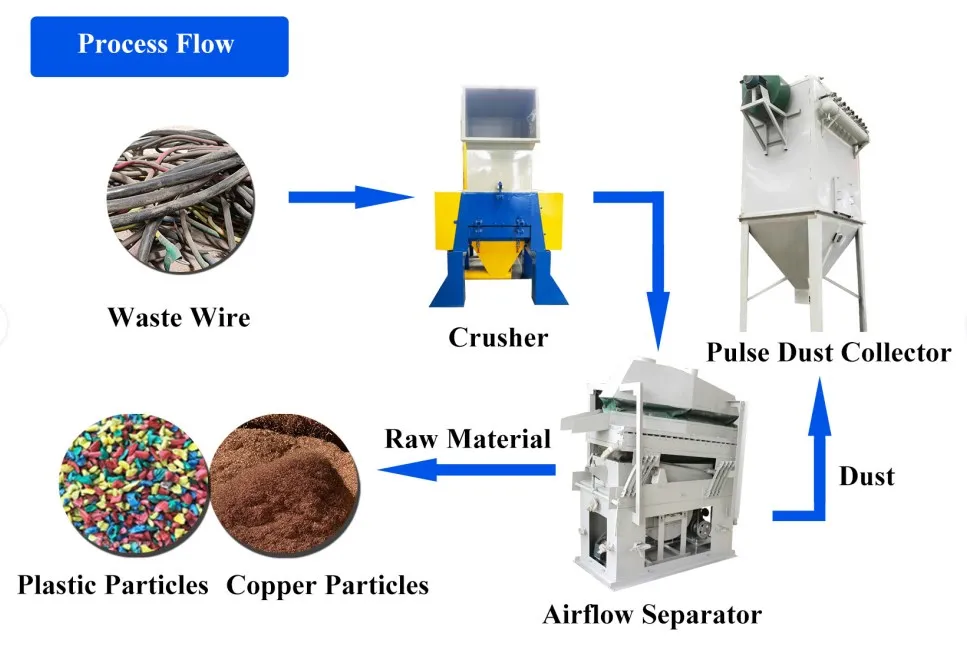

Copper Wire Granulator Cable Recycling Machine Copper Plastic Separation Machine

|

Model

|

Capacity(KG/H)

|

Power(kw)

|

Size(mm)

|

Weight(KG)

|

|

YT-TMJ-200

|

100-200

|

30

|

2400*1800*2800

|

2390

|

|

YT-TMJ-500

|

300-500

|

53

|

6000*6000*4600

|

4790

|

|

YT-TMJ-1000

|

800-1000

|

154

|

20000*12000*4600

|

12000

|

|

Model

|

Capacity(KG/H)

|

Power(kw)

|

Size(mm)

|

Weight(KG)

|

|

YT-TMJ-200

|

100-200

|

30

|

2400*1800*2800

|

2390

|

|

YT-TMJ-500

|

300-500

|

53

|

6000*6000*4600

|

4790

|

|

YT-TMJ-1000

|

800-1000

|

154

|

20000*12000*4600

|

12000

|

Contact : CUI SHENG, 86 18530843555

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Copper Wire Granulator Cable Recycling Machine Copper Plastic Separation Machine Search in a category : B2B Services Search in a category : machine, granulator, copper, recycling, plastic, wire, cable |

Monday, August 20, 2012

Quantity : une machin - Price : 30000euros

Location : Calle Prado Isidro 45 , 28492 Mataelpino Madrid, Contact : Allami Azizi cherifa, 639509955

autonomo

- 28492 - Mataelpino Madrid

- 639509955

Monday, September 07, 2015

- Feature (click here for details) - - Under the LAN can support more than 10 simultaneous client connections cameras, image lag within 100 milliseconds, supports standard streaming media network protocols, network 8 M per channel bit rate case, no mosaic - The DSP processor...

ZT Technology Group Ltd.

- ellazhan

- 852 - Fo Tan

- +85 2 26 75 75 58

Sunday, July 26, 2015

We love what we do. No matter what item we are dealing in, we try our best to provide our customers with the best quality products and services. We feel very proud with our customers' responses. We like nothing more than to hear from our customer and invite them to reach us any time...

TRADEX GROUP CO LTD

- 15140 - opburi

- +6661409539