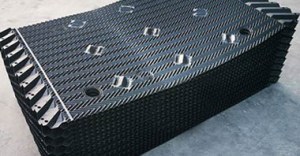

Cooling Tower Filling

Our cooling tower inc provides cooling tower filling, drift eliminator, fan, motor, gearbox, belt reducer, spray nozzle, sprinkler head, float ball, air inlet louvers, etc... Whatever cooling tower parts you need, you will find them in our cooling towers LLC AUVC.

As a cooling tower fills manufacturer, as well as pvc fill for cooling tower suppliers, we supply different materials for the fills with good cooling tower pvc fills price such as PP and PVC. The honeycomb design principle is adopted, which is an important part of cooling tower. The function of fill in cooling tower is to increase heat dissipation, prolong the residence time of cooling water, increase heat exchange area, and distribute water evenly.

Types Of Fills In Cooling Tower

Cooling Tower Filling For Mesan

Product Description: cross flow tower, can only be suspended, tilt angle 5.5 degrees, suspended. It is suitable for the maintenance and renovation of cooling towers of Marley, Xinling, Yuanheng and Lanxun brands.

Cooling Tower Filling For BAC

BAC cooling tower filling is one of the most important parts of the heat exchange process of the cooling tower. It is also the main part to improve the efficiency of cooling tower and ensure the economy and safe operation.

Cooling Tower Fills Specification

Feature 1: The cooling fill media in cooling tower adopts inclined suspension installation and the bottom of the filling is suspended. This way the cooling tower will not deposit debris and the water will flow smoothly, preventing algae and bacteria from growing.

Feature 2: No glue bonding, no deformation, no embrittlement, effectively solve the problem of filling scaling. The old installation method used glue bonding, and the filling was stacked in the cooling tower. When it was used, the bonding point of the filling was easy to scale, which accumulated over time and collapsed after serious bending deformation, thus affecting the cooling performance.

Feature 3: Increase the effective air intake area. More steel frame is needed to support the bottom of the bonded filling, which reduces the effective air inlet area of the filling, while the suspended installation of the fill media in the cooling tower does not need to support the steel frame.

Feature 4: Filling installation, transportation, and maintenance are simple and convenient.

Advantages Of Cooling Tower Filling

a.There is no geometric deformation at 65 ℃ - 35 ℃.

b.It is not broken or brittle under the design temperature.

c.Under normal operation and service conditions, its service life shall not be less than 20A.

d.High thermal performance, far more than 90% of the national standard requirements;

e.The floating water rate is lower than 0.001% of the circulating water volume, and the three in one design of self-contained water collector and air inlet louver is adopted; the filling is made of flame retardant PVC vacuum molding,

f.It has good flame retardancy.

Attention Requirements For Cooling Tower Filling

a. Removal of the old cooling tower filling, turn off the power supply of the motor; removal of the cooling tower filling reinforcement; removal of the old filling; tower garbage cleaning; cleaning up the site;

b. Due to a large amount of bonding, in order to ensure that there is enough space for the filling binder to be placed during curing, the contact point should be on the same horizontal plane during bonding, so as to ensure that the force on the contact point of the filling is uniform and tight during crimping;

c. Clean up the floating dust and garbage on the internal parts of the cooling tower to ensure cleanliness. Place the filling blocks in the cooling tower in turn. It is strictly forbidden to squeeze the filling during the process. Ensure that each layer of the filling block is neat and tight, and the filling is tight and seamless with the corner and column;

d. Pay attention to the up and down direction of the assembly block during installation. The top surface of each layer should be laid flat, and the interlayer should be cleaned, and there should be no debris blocking.

e. When installation, maintenance, and other work need to work on the filling, it must be paved with a flat plate, and it is strictly forbidden to step on it directly.

f. In the process of construction, assembly, and installation, it is strictly forbidden to weld above the filling of the cooling tower, and fire prevention measures shall be taken when necessary. After installation, all construction tools and facilities are waiting for acceptance, and the whole filling replacement procedure of the cooling tower is completed.

Advantage of Cooling Tower Filling

a. The raw materials of cooling tower fill are PVC and PP, with good toughness, no white line and aging resistance.

b. By vacuum molding, the volume heat dissipation quality is high.

c. The service life of cooling tower fill is generally more than 10 years.

d. Vacuum pressure forming. The unique fill curve ensures the high efficiency of heat transfer.

e. The bearing capacity of cooling tower fill is large, and the bearing capacity per square meter is more than 3.5kn.

f. Good chemical stability, acid, alkali and organic solvent corrosion resistance.

g. The product has strong hydrophilic property, good film-forming property and easy to conduct the heat of filler.

Contact : AUVC ctauvc, 057582331987

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Cooling Tower Filling Search in a category : Second hand goods Search in a category : filling, tower, cooling |

Friday, December 15, 2017

OEM PART NO DESCRİPİTİON 66072 Crown Wheel and Pinion FOR CARRARO 13X30 66941 Crown Wheel and Pinion 15x37 2277448 CATERPİLLAR AİR FİLTER OUTER 2277449 CATERPİLLAR AİR FİLTER İNNER 01/117901 FAN BELT 01/124403 FAN BELT 01/124404 02/100073 Oil Filter Canister Type, MEDİUM MODEL 02/100284...

ANAC MAKINA CO LTD STI

- 34800 - İSTANBUL

- +905069691531

- +9005069691531

Wednesday, September 14, 2016

Quantity : 5000 - Price : 50,00 €

Gland Packing Globe Valves ( Straight- Through Type) DIN Standard Gland Packing Globe Valve DIN Globe valve DIN Stop valve DIN Absperrventil Durchgangsform DIN Válvulas de globo DIN ventil uzavírací s klasickou ucpávkou přímý DIN Standard seteventiler med pakkboks (rett løp...)

ETM Armaturen

- 59590 - Henri Durre

- 86 577 67953935

Tuesday, September 24, 2013

Quantity : 1000 - Price : 1 000,00 €

ASME SA213 T11,ASTM A213, ASTM A213 T11, SA213 T11, Alloy steel pipe, Alloy tube ASTM A213 T11 is the part of ASTM A213 Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, Heat-Exchanger Tubes. ASTM A213 T11 is the part of ASTM A213 Standard...

Sunny Steel Tubosacero Ltd.

- tubosacero

- Shanghai - 闸北

- 862133780199

- 862161851035