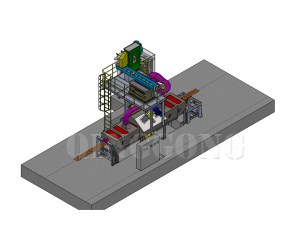

ANCHOR CHAIN SHOT BLASTING MACHINE

The working principle for shot of anchor chain shot-blasting machine is mainly by numerous high speed abrasive flow projection to the anchor chain surface, which blast cleaning the oxides and Surface attachment from the anchor chain, and by making the surface plastic deformation to effectively improve the chain's fatigue strength and fracture resistance of corrosion.

The working principle for anchor chain shot blasting machine china is mainly by numerous high speed abarsive flow projection to the anchor chain surface, which blast cleaning the oxides and Surface attachment from the anchor chain, and by making the surface plastic deformation to effectively improve the chain's fatigue strength and fracture resistance of corrosion. Main composition and structure characterized by shot blasting Chamber, sealed rooms, elevators, separators, screw conveyors, throwing Assembly, Abrasive reclaim system, elevator platform, inbound and outbound guide wheel unit, abrasive dosing unit, foundations, dust collecting systems, electrical control components.

Ship anchor chain used shot blasting machine is a tailored equiupment which design based on end user's requirements of the equipment performance, it can process φ22 to φ50 anchor chain for one-time blast cleaning.

Applications

Removal of mill and forge scale as well as rust

Removal of burrs and scales

Removal of moulding sand

Increase of surface roughness

Shot peening to increase fatigue strength

Contact : Sara Sara Li, 0532 82121566

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of ANCHOR CHAIN SHOT BLASTING MACHINE Search in a category : B2B Services Search in a category : chain, machine, blasting, anchor, shot |

Friday, February 27, 2026

Action return pallets for wholesalers, professional clearance and European expor

Quantity : 30000 - Price : 0,50 €

We offer return pallets exclusively composed of products sourced from the Action retail chain, intended for wholesalers, clearance professionals, resellers, and exporters. These liquidation pallets contain non-food fast-moving consumer goods, carefully selected for their high resale potential and quick turnover. Offer details: - Return pallets from large retail distribution – Action brand - Approx. 1,000 items per pallet (80% of pallets) - Average price: around €0.50 per item...

TRANSIDI

- 22440 - PLOUFRAGAN

- 09 72 63 03 26

- 33(0)603670505

Friday, May 16, 2014

Quantity : 5000000 - Price : $0.50-5/pc

Precision CNC Machining Part Factory Company Profile: Fully equipped with advanced CNC machinery, we have rich experiences to manufacture precision machined parts, turned parts, milling parts as per the drawings to deliver you the top-notch products. Our manufacturing facilities...

Xiamen Karo Co.,Ltd

- karoplastic

- 361002 - Xiamen

- 0086 592 5135406

Wednesday, April 22, 2015

Quantity : 1piece - Price : USD5~36

1 Ashiloy Industry co,ltd solar panel: 3W 2 Lithium Battery: 3.7V / 4400mA high quality full capacity battery. 3.LED: power 3W, 38pcs. Epistar SMD 2835LED , color temperature 5500-6000K, lumens about 300LM. Brightness equivalent to 12 watts of brightness tricolor energy-saving...

Ashiloy Industry Co.,Ltd

- 999077 - KLN

- +86 138235618632