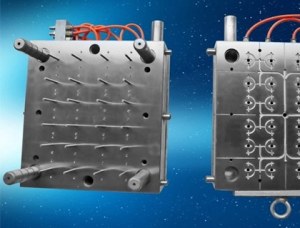

SYRINGE MOLD/MOULD

LINKPLUS provide precision molds used in manufacturing of each components of the various syringes such as disposable syringe, Insullin syringe, safety syringe, AD syringe. Including barrel, plunger, gasket. It's customizable according to customer production need. Our syringe mold design is reasonable, with a sturdy structure and stable performance, which can greatly improve production efficiency and mold service life.

WHAT IS SYRINGE MOLD USED FOR?

Syringe molding is a specialized tool used in the manufacturing of syringes. It is designed to produce precise and consistent shapes of plastic or glass components that make up the syringe, including the barrel, plunger, needle cap, needle hub and so on.

HOW DO YOU USE SYRINGE MOULD?

Steps for mold installation.

1

Confirm that the injection molding machine power is turned on.

2

Click the manual button of the injection molding machine to put it in manual mode.

3

Click the oil pump button of the injection molding machine to start the oil pressure system of the injection molding machine.

4

Transport the molds in place and confirm that they match the production accessories.

5

Use a sling to slowly lift the mold slightly above the injection molding machine, and move the sling bracket so that the mold is above the installation position. Be careful not to cause the mold to collide with the surveillance camera and robotic arm.

6

Slide the protective sleeve of the injection molding machine guide pillar to the appropriate position and slowly lower the mold. The operator should support the top of the mold to avoid it Intense shaking. The operator must control the mold and prohibit it from hitting the guide pillar. When the guide pillar is hit, it will cause concave and convex deformation, Damaging the sealing of the oil pressure system.

7

Lower the mold to the appropriate position, install the positioning flange and protective ring, adjust the mold and sling bracket to make the mold flange and protective ring fit with the injection hole of the injection molding machine.

8

Close the sliding doors on both sides of the injection molding machine, click the mold adjustment button of the injection molding machine, and enter the mold adjustment state.

If you are looking for a reliable medical molding manufacturer, don't hesitate to contact us!

Contact : com Welinktech, 0577 88919099

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of SYRINGE MOLD/MOULD Search in a category : B2B Services Search in a category : mold, mould, syringe |

Monday, July 20, 2015

maroc, vente, plastique recyclée, fournisseurs, distributeurs, importateurs, producteurs , grossistes, import, export. Société italienne spécialisée en production d'un polymère innovant produits parmi le recyclage de polyoléfine et polypropylène cherche importateurs utilisateurs...

impresa in marocco sarl

- 20000 - CASABLANCA

- 06 29 90 85 75

Thursday, October 08, 2015

Price : 900euros

H.S. Code: 39041090 Purity: 99% Apparence: White powder or Grain 1. virgin hdpe granules Characteristic This HDPE granulate is the extrusion, pipe grade with good weather resistance,good disper sion of black carbon also excellent resistance to rapid crack propagation resistance and...

SA BANGKOK IMPORT AND EXPORT LTD

- 10110 - Bangkok

- +66 9 40 61 68 72

Thursday, June 04, 2015

Quantity : 24000

The Théveste Import-export Ltd, International Corporation business immatriculée à Tébessa -Algérie, cherche à acquérir une grande quantité de Ciment Portland à Haute Résistance aux Sulfates (HRS) conforme à NT 47.01 et NT 47.26, appartenant à la Classe de résistance 42,5 dont voici...

Teveste Import-Export Limited

- 12000 - Tébessa

- +21 3 79 57 18 99