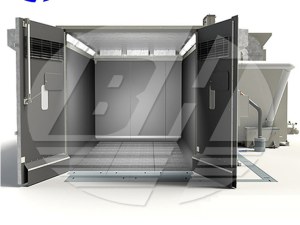

Sand Blasting Container

It is mainly composed of shot blaster assembly, shot blasting room, trolley transportation system, dust removal system, electrical control system and other parts.

Composition of Sand Blasting Container

It is mainly composed of shot blaster assembly, shot blasting room, trolley transportation system, dust removal system, electrical control system and other parts.

1. Shot blasting room

The shell of the shot blasting cleaning room is made of color steel rock wool sandwich composite board and rectangular steel welding riveting structure, which is a strong, sealed and spacious operation space for shot blasting of the workpiece. The shot blasting cleaning room is composed of the left and right side walls, the rear sidewall, the top plate, the rubber guard plate, and the gate. The shot blasting room is equipped with metal halide lamps (protected by stainless steel mesh). The interior of the chamber is protected by white wear-resistant rubber guards, and all guards are installed with bead bolts. The door of mobile sandblasting unit adopts container type manual folio.

2. Shot blaster assembly

The shot blaster assembly is composed of a tank, a nozzle, a nozzle, a pneumatic element, etc. It is a large-capacity continuous operation double-gun shot blaster. The nozzle is made of boron carbide and is durable. The nozzle is made of ultra-wearable high-pressure rubber tube Among them, the production of tanks has the qualification of making pressure vessels.

3. Pill material circulation purification system

The pellet circulation purification device includes a circulation system and a pellet separation purification system, which is composed of a screw conveyor, a bucket elevator, a pellet sand separator, a pellet supply gate valve, and a pellet delivery pipe.

Screw conveyor:

The screw conveyor is composed of a casing, a screw shaft, a bearing with a seat, a drive mechanism, etc. It is a serialized part of our company, with high versatility, high interchangeability, and stable and reliable performance.

This component is responsible for conveying the shot sand mixture to the elevator. The screw conveyor is located at the bottom of the shot blasting cleaning chamber, and the screw blades are welded to the drive shaft. When working, the conveyor motor drives the screw conveyor to rotate through the cycloid reducer to transport the pellets to the discharge port, and then the discharge port transfers the scattered pellets and dust mixture to the bottom of the elevator.

The two ends of the screw conveyor are protected by a three-stage seal, a labyrinth seal cover is added inside the end plate, an oil seal is used for protection in the middle, and the bearing is separated from the end plate outside the end plate. Once the pellets and dust are extruded, they will fall from the gap between the end plate and the bearing and will not enter the bearing.

Bucket elevator:

The bucket elevator is composed of cycloidal pinwheel speed reducer, upper and lower rollers, conveyor belt, hopper, closed barrel and tensioning device, etc., and centrifugal gravity is used for blanking.

When working, the hopper fixed on the conveyor belt scrapes the pellets at the bottom and sends the pellets to the top, and then falls by centrifugal gravity. Adopting special transmission belt of polyester wire core, high strength and high tensile performance.

The pulley adopts a squirrel-cage structure with a slight protrusion in the middle, and each spoke is processed by chamfering. It not only improves the friction between the lifting tape and the pulley, avoids the slipping phenomenon of the old-fashioned light pulley and the pulley to the belt, but also reduces the pretension of the lifting belt and extends the service life; at the same time, it avoids the embedding of scattered bomb Between the pulley and the belt affects the transmission.

There is a 10% margin for the lift. Because the hoist falls by centrifugal gravity, each time it falls, there will always be part of the material falling back into the hoist, so it is necessary to increase the lifting amount appropriately.

Pellet separator:

This machine adopts the world's most advanced full-curtain flow curtain air separation pill residue separator, and its separation efficiency is ≥99.5%. This separator is the latest type of separator of our company. The separator is one of the key components of this equipment. The design size of the separation zone directly affects the separation effect of the separator. If the separation effect is not good, it will accelerate the wear of the blasting blade.

4. Trolley conveyor system

Flat car transportation is adopted; the load-bearing is customized according to the actual situation of the customer. According to the condition of the workpiece, manually push the flat car into the cleaning room to receive shot peening. The front of the wheel can be equipped with a polyurethane scraper to scrape off the projectiles above the rail.

5. Dust removal system

Dust removal system includes a filter cartridge dust collector, fan, motor, pipeline, chimney, etc.

Automatic pulse back-flushing, dust-removing valve adopts pneumatic control, and a dust collecting barrel with a roller is arranged under the ash hopper, to avoid the secondary dust phenomenon caused by back-flushing

The dust filter cartridge can be easily removed for cleaning and reuse.

6. Electrical system

Industrial mobile sandblasting equipment, maintenance door, projectile controller and projectile circulation system are all equipped with electrical interlock and self-locking mechanisms to ensure the reliable operation of equipment and the safety of operators. The dust blower back blowing adopts automatic pulse control.

We have commercial sandblasting equipment for sale, mobile shot blasting equipment for sale, industrial sandblasting equipment for sale, welcome to buy.

As the shot blasting companies, Sand blasting room is primarily for cleaning big steel structural parts, vessel, truck chassis to remove the rusty spot, rusty layer and scale cinder on steel to obtain a uniform, smooth and glossy metal surface allowing improved coating quality and higher anti-corrosion performance. It is used in a wide variety of industries that require surface preparation prior to the application of a protective coating. Sand blasting Machines clean or shape a surface using sand material known as abrasive which is propelled using high pressure typically through compressed air or blast wheel. Sand Blasting Machine are many types such as Sandblasting Cabinet, Container Blast Room, Automatic Sand Blasting Machines and so on.

Contact : Xenia Lee, 0532 88068506

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Sand Blasting Container Search in a category : Everything else / Bulk Search in a category : container, sand, blasting |

Saturday, April 25, 2015

Specifications: Nominal voltage: 6V Nominal capacity (20HR): 4Ah Maintenance: Free Dimension(LxWxHxTH): 70x48x100x106mm Weight/unit: 0.68kg Advantages: * Full range of lead acid battery, with capacity 0.8Ah to 3000Ah * Maintenance-Free * Completely safe and sealed design *...

HUAWEI POWER SOURCE (HONG KONG) CO., LTD

- 0000 - TSUEN WAN

- +85 2 31 88 23 29

Tuesday, February 17, 2026

Quantity : 1

The fryer model GP are automatic machines equipped with auxiliary belts are the best solution for the production of pellets. - Built in stainless steel sheet AISI 304 according to rules of machines and pellets Line, snack, nuts, grains, rinds, potatoes, chipsseguridadalimentaria...

Mafrigarlo

- mafrigarlo

- 28970 - humanes de madrid

- 91 6971596

Tuesday, February 17, 2026

Quantity : 30 - Price : 1 800,00 €

Info and order please visit www.xtremestorebali.net - FrameGenius Carbon / IMP / HMX net BB 92 / Carbon swingarm with 180PM U-Mono Link / Tapered Headtube IDS SL dropouts for 142 x 12mm BB height adj. - ForkFox 32 Float Factory CTD FIT Air / Kashima CTD remote damper with 3 modes...

Xtreme Store Bali

- 80361 - Bali

- 6285270708959