Ring die wood pellet mill

Quantity : 15-20 sets Price : USD 1500-2000 per se

Ring die wood pellet mill belongs to pellet fuel processing equipment.After the materials like sawdust, wood logs, rice husk, sunflower seed shells, peanut shells, and other kinds of agricultural waster are first ground by a hammer mill and dried to a moisture content about 15%,they can be processed by our ring die pellet mill into solid biomass pellets. The final wood pellets can be used in stoves for home heating and industrial boilers and large power plants. Besides, the pellets are also widely used for animal bedding.

Wood Pellets Benefits

1. Compared with raw wood shavings, there is less ashes and emission after combustion, carbon neutral without exacerbating the global warming.

2. Raw materials are easy to get. Wood materials, agricultural byproducts, even wood waster from wood processing factory can be utilized to make wood pellets.

3. Easy to ignite due to low moisture content.

4. Efficient burning and high heat output.

5. It can be used in a lot of appliances such as stoves. furnaces, boilers and other heating systems.

6. Highly compressed, regular and uniform shape ensures easy storage and transportation, especially convenient for automated heating system.

Ring Die Wood Pellet Mill Features

1. Adopt high precision gear drive. Output is 20% larger than of belt drive.

2. Advanced bearing and oil seal guarantee a efficient and stable working process.

3. Feeding device adopts frequency conversion motor, ensuring continuous and even feeding

4. Different hole-diameters make various sizes of pellets possible.

5. Flexible coupling shaft with novel structure ensures a stable pelletizing process and low breakdown possibility.

6. Permanent magnet device can remove impurities process.

Ring Die Wood Pellet Mill Working Principle

After grinding and drying process, the materials will be sent into feeding device and mixed in the conditioner. Then they are forced into the pelletizing chamber by the imperative feeder. In the chamber, materials are squeezed between the rollers and die to form into cylinder shape pellets. As they are extruded, cutting knives will cut the pellets into specified size.

Ring Die Pellet Mill for Making Wood Pellets Specification

|

Model |

Power |

Capacity |

Dimension |

|

MZLH320 |

37kw |

0.3~0.5t/h |

2100*800*1300mm |

|

MZLH350 |

55kw |

0.4~0.6t/h |

2200*900*1500mm |

|

MZLH400 |

75kw |

0.8~1t/h |

2300*1000*2100mm |

|

MZLH420 |

90kw |

1~1.2t/h |

3200*1100*1700mm |

|

MZLH508 |

132kw |

1.5~2.2t/h |

3200*1300*1900mm |

Contact : allance kala, 86 0371 65950319

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Ring die wood pellet mill Search in a category : Equipment goods Search in a category : ring, mill, pellet, wood |

Friday, March 22, 2024

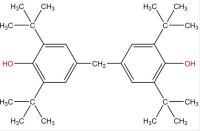

2,2',6,6'-tetra-tert-butyl-4,4'-methylen ediphenol Synonym: 4,4ʹ-methylenebis (2,6-di-tertiary-butylphenol) Phenol, 4,4-methylenebis(2,6-bis(1,1-dimethyleth)) )- PowerNox™ 4426 has extreme low volatile. It is used for synthetic resin antioxidants due to its resisting thermal oxidation...)

TinToll Performance Materials Co., Ltd.

- 225400 - Jiangsu

- 025 58599930

Tuesday, May 30, 2023

Quantity : 50 - Price : 3 239,00 €

Buy 2022 Felt IA Advanced Ultegra Triathlon Bike from Calderacycle is 100% safe, Because purchase products at Calderacycle provide 100% moneyback guarantee To purchase online visit our website : https://calderacycle.com Price : USD 3239 Min Order: 1 Unit Lead Time: 7 Days Port : Kualanamu...

CALDERACYCLE

- 20226 - Medan

- +6282268116904

- 628973908676

Wednesday, September 06, 2023

Quantity : 20 - Price : 4 119,00 €

Buy 2022 Felt IA Advanced Ultegra Di2 Triathlon Bike from Calderacycle is 100% safe, Because purchase products at Calderacycle provide 100% moneyback guarantee To purchase online visit our website : https://calderacycle.com Price : USD 4119 Min Order: 1 Unit Lead Time: 7 Days Port ...

CALDERACYCLE

- 20226 - Kota Medan

- +6282268116904