Over Molding

Over molding of keyplast is a special plastic molding process. Overmolding custom injection molding is similar to the two-color molding or two-shot molding process. Over moulding can make the surface of the product full of softness and increase product functionality and added value.

With this technology, product functions can be increased, such as noise reduction, vibration reduction, waterproof, anti-collision and added value. Overmolds is widely used in mobile phone protective shells/mobile phone protective sleeves.

Overmolding Process

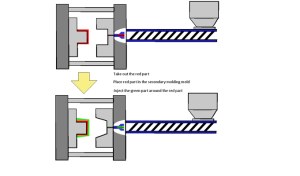

Plastic overmolding has a process in which a certain materials used in injection moulding is molded in a primary plastic mold, and the molded part is taken out and placed in a secondary molding mold to inject the same or another plastic materialinto tpu overmolding process. Overmolding process has key factors as below:

1. The chemical or mechanical bonding strength between the polymers is not enough, and the material of single or multiple parts is not completely filled;

2. Flashing of burrs on single or multiple material parts.

3. The injection molding machine must maintain the consistency of injection molding.

Insert Molding VS Overmolding

Insert molding and overmolding injection molding are very similar, but there are significant differences between the two processes. Injection overmolding is a two-step process in which two separately molded parts are combined to enhance product functionality. While insert injection molding is a slightly faster process because the two plastic materials are molded at the same time. Besides, over molding can not only give designers and engineers more creative freedom, but cost-savings of assembled parts as well. Whether you choose insert molding or over moulding, we understand the importance of creating a strong bond between components. We'll recommend the right innovative polymer solution, like thermoplastic polyurethane overmolding (TPU overmolding) to deliver the chemical adhesion you need.

Overmolding VS Two Shot Molding

01

Two-shot injection molding

Two-shot injection molding is also called two-color mold injection. 2 shot injection molding, also called 2k injection moulding, is to inject two plastic materials on the same injection molding machine in two moldings, but the product is only ejected once. The mold is usually completed by a set of molds and requires a special two-color Injection molding machine.

The same back mold, different front molds, high production efficiency, good product quality, suitable for mass production.

02

Over molding

Over molding, the two plastic materials are not necessarily injected on the same injection molding machine, but are molded in two parts; after the product is taken out from one set of molds, it is placed in another set of molds, inject molding. Therefore, this molding process is usually completed by two sets of molds, without the need for a special two-color injection molding machine.

Injection overmolding is to first take part of the product out of injection molding, and then put it into another injection molding machine for injection molding. The efficiency will be slower and the cost will be higher, so it is suitable for small batch production.

Why so many manufacturers like over molding?

Regarding this problem, we can learn one or two of the advantages of overmolding injection molding.

First, the product quality of over-molding can be improved. Injection overmolding can optimize the copolymerization of hard and soft materials to form strong molecular bonds. The result is a single part with production and feature advantages. It can be used for various product designs in injection moulding applications. The injection overmolding also allows the use of transparent plastics, colorful graphics, and fashionable finishes for molding, thereby improving your product functionality and market value.

Second, plastic injection overmolding can reduce the cost of production. Complete the entire production process in one injection molding machine, overmolding injection molding effectively reduces unit costs, reduces processing and secondary assembly, and reduces costs and waste associated with assembly defects, thereby shortening the molding cycle and improving work efficiency.Furthermore, china injection molding factory can also improve people's experience. Over the past 10 years, it has completely changed the aesthetic standards, design ideas, and functional requirements of consumer products. The use of plastic materials with different textures has improved the touch and function of products. Many of the common toothbrushes and mobile phone protective cases in our lives are products produced by using injection overmolding technology.

Contact : Hu Harry, 86 576 84288218

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Over Molding Search in a category : Second hand goods Search in a category : molding |

Thursday, October 08, 2015

Price : 900euros

H.S. Code: 39041090 Purity: 99% Apparence: White powder or Grain 1. virgin hdpe granules Characteristic This HDPE granulate is the extrusion, pipe grade with good weather resistance,good disper sion of black carbon also excellent resistance to rapid crack propagation resistance and...

SA BANGKOK IMPORT AND EXPORT LTD

- 10110 - Bangkok

- +66 9 40 61 68 72

Thursday, June 04, 2015

Quantity : 24000

The Théveste Import-export Ltd, International Corporation business immatriculée à Tébessa -Algérie, cherche à acquérir une grande quantité de Ciment Portland à Haute Résistance aux Sulfates (HRS) conforme à NT 47.01 et NT 47.26, appartenant à la Classe de résistance 42,5 dont voici...

Teveste Import-Export Limited

- 12000 - Tébessa

- +21 3 79 57 18 99

Monday, July 20, 2015

maroc, vente, plastique recyclée, fournisseurs, distributeurs, importateurs, producteurs , grossistes, import, export. Société italienne spécialisée en production d'un polymère innovant produits parmi le recyclage de polyoléfine et polypropylène cherche importateurs utilisateurs...

impresa in marocco sarl

- 20000 - CASABLANCA

- 06 29 90 85 75