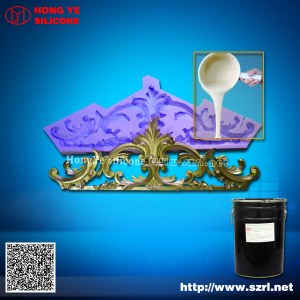

Mold making silicone rubber

mold making silicone rubber

HY625,HY630 ,HY635 6-9USD/KGS

Specification

- Durable

- High tear strength for replication

- Low shrinkage

- High simulation

- Cover fine details

mold making silicone rubber application

mold making silicone rubber is primarily intended for mold making of gypsum, concrete, poly resin ,PU resin, unsaturated resin crafts, lighting and candles crafts , plastic toys , stationery gifts crafts industry, large statue, Buddha, relievo furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, large-scale cement mold, artificial fossils Factory, European buildings, simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

mold making silicone rubber description

mold making silicone rubber is a kind of flowable liquid silicone, the quality has nothing to do with the color. It consists of two components. Part A is a flowable liquid silicone rubber, part B is the curing agent. Firstly, after your previous work of dealing with the original model, take some liquid silicone rubber , add 2%-3% curing agent of the amount of silicon, and mix them evenly. Then after vacuum-pumping the mixture, you can pour it into the mold frame. The silicone mold will cured in 2-4 hours.

mold making Silicon rubber datasheet

Model: 625# mold making silicon rubber

Appearance: white

Viscosity (cs): 17000-20000

Hardness (A): 24-26

Tensile strength(kgf/cm2 ) ≥32

Tear strength (kgf /cm): ≥28

Elongation break(%): ≥500

Retractility (%): ≤0.2

Curing agent mixed rate (%): 2-3

Operate time (min): 30

Curing time (hours): 2-4

Model: 630# mold making silicon rubber

Appearance: white

Viscosity (cs): 19000-25000

Hardness (A): 28-32

Tensile strength(kgf/cm2 ) ≥35

Tear strength (kgf /cm): ≥30

Elongation break(%): ≥470

Retractility (%): ≤0.2

Curing agent mixed rate (%): 2-3

Operate time (min): 30

Curing time (hours): 2-4

Model: 635# mold making silicon rubber

Appearance: white

Viscosity (cs): 30000-33000

Hardness (A): 35

Tensile strength(kgf/cm2 ) ≥40

Tear strength (kgf /cm): ≥32

Elongation break(%): ≥450

Retractility (%): ≤0.2

Curing agent mixed rate (%): 2-3

Operate time (min): 30

Curing time (hours): 2-4

mold making silicone rubber features:

1. Good characteristics of easy-operation

2. Light viscosity and good flowability

3. Low shrinkage

4. Excellent tensile and tear strength

5.Favorable hardness

6. High temperature resistance, acid and alkali-resistance and ageing resistance

7. High duplication times

Contact : hanks lee, 86 0755 89948006

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Mold making silicone rubber Search in a category : Raw materials Search in a category : silicone, rubber, mold, making |

Thursday, February 01, 2024

Shecare Smart Bluetooth Basal Thermometer Smart Basal Thermometer What thermometer to use for basal body temperature? shecare basal body thermometer with app is a kind of bluetooth basal body thermometer automatically synchronized with the body temperature thermometer app via Bluetooth...

Shecare-ikangtai

- 100084 - Haidian

- 86 010 56231097

Thursday, August 11, 2022

Quantity : 1500/matri - Price : 482,00 €

More About Our Brand Best Quality Wheat Flour - ABC Brand - Best Price - ISO Certified - 50 KG Brand ABC Wheat type High Quality Hard Wheat Purpose Cake, Bread, Bakery, Biscuits Protein 11.5% min Gluten 24% to 25% min Moisture 14% MAX Ash 0.65 MAX ...

BOOM PLUS FOR MANUFACTURING AND COMMERCE

- 002 - Cairo

- 00201220066112

- 00201220066110

Monday, April 26, 2021

Quantity : 1 - Price : 0,10 €

医用一次性设备的一次性压力延长线/管 Lonyi的PVC管/导管使用医用PVC原材料,并在10000/100000级的 清洁车间中挤出。 尺寸,颜色和结构可根据客户要求制作。 可用于制造多种医疗器械,如莱文斯管延长线,进料管,吸管,氧气管等。 物品 说明 名称 用于医疗一次性设备的一次性PVC管。 材料 不含DEHP的医用级PVC。 尺寸 定制。 颜色 定制。 应用 用于医疗设备。 外貌 管壁厚度均匀,表面光滑,无裂纹, 无气泡,无杂质,无味,无毒。 认证 ISO13485。 交货时间 收到预付款后的20-25天。 包裹...

- 318118 - Shenzhen

- +86 199 2531 6571