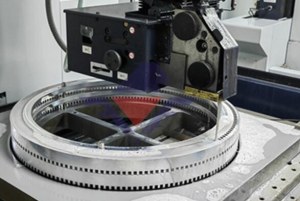

Micro Machining

Advantage of Micro Turning

Precision

Falcon Micro Machining Service sets a benchmark for precision machining, utilizing state-of-the-art equipment and expert craftsmanship to achieve intricate tolerances and exacting specifications, guaranteeing the highest level of accuracy and quality in every machined part.

Efficiency

By leveraging advanced machining methodologies and automated systems, Falcon Micro Machining Service streamlines production workflows, reducing cycle times and increasing productivity. This optimized efficiency allows for faster project completion and shorter lead times, enabling clients to meet tight deadlines and improve overall operational efficiency.

Customization

Recognizing the diverse needs of clients, Falcon Micro Machining Service offers extensive customization options. Their team of experienced engineers collaborates closely with customers, providing personalized solutions tailored to unique requirements. This flexibility ensures the production of custom machined components that perfectly align with specific applications, industries, or design specifications.

Difference Between Micro Machining And Other Types Of Machining

Micro precision components and other types of machining are similar in that they involve cutting, shaping, and drilling materials to create parts or components. However, micro machining involves creating parts and components on a much smaller and more precise scale than traditional machining processes. Micro machining uses advanced CNC (Computer Numerical Control) machines and specialized cutting tools to operate at a microscopic level, and it is typically used to produce parts with dimensions of millimeters and micrometers. Other types of machining typically produce larger parts or components using standard machine tools. Micro machining requires a high level of technical expertise, specialized equipment, and precision calibration to produce highly accurate parts.

Contact : con Fal, +18 5 89 03 24 77

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Micro Machining Search in a category : Feasts items Search in a category : machining, micro |

Wednesday, April 08, 2015

Quantity : 100 grams - Price : 10USD

Food Grade Silicone Rubber Description Food grade silicone rubber It have FDA Certificate and excellent for high-detail cake molds and comp lex design. Also it very suitable for making ice trays molds , baking molds,casting butter and other application you can image to produce foods...

Guangzhou OTT New Materials Co.,Ltd.

- 510800 - Guangzhou

- 86 020 86819712

Wednesday, December 26, 2012

Quantity : 100 - Price : 1,35 €/pce

Sell prizes(lots) of pacifiers natural DELUX, colors pink(rose), sky blue, dark blue, red, white, beige. Cut 6-36 months. Pacifiers are virgin and do not contain either writing, or drawings. Ideal for the customization(personalization)!!! They are sold by prize(lot) of 100 rooms(parts...)

SNET

- 77694 - KEHL

- 06 01 29 17 70

Tuesday, June 16, 2015

Quantity : 10000m2/we - Price : USD 80-90/m2

Air slide belt Airslide Belt (pneumatic conveyor belt) has fine breathability, it is used for pneumatic conveyors o f bulk materials. It is an indis pensable part of cement industry, aluminium, lime and gypsum indust ry, coal-fired power stations, transport of bulk goods, chemical industry ...

Huatao Wire Belt Factory

- 050000 - shijiazhuang

- 86 311 80772027