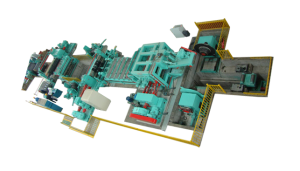

Medium Gauge Slitting Lines

Quantity : 20 Price : 20,000 USD - 800,000

RISHBIN Medium Gauge Slitters is used to slit the big rolls into narrow rolls, and packaging it automatically. It works of max. thickness up to 10mm, max. width of up to 2200mm, and speed of up to 100 m/min. It consists of Decoiler with coil car, guiding & pinch device, medium gauge slitters, dual head/quick tooling change for the auto slitting machine is available, scrap winder, side-guiding device, looping, tension device, recoiler. Different materials could be suitable to be processed in the line, such as pre painted steel coil, cold rolled steel coil, hot rolled carbon steel coil, stainless steel coil, copper, brass, aluminum and titanium. These narrow coils/rolls are widely used in Steel Pipe Factory, Steel Structure Factory, Storage System Manufacturing Factory, combined with Roll Forming Machine, Power Punch Machine, Pipe Mills.

To help you achieve your own production capacity target, RISHBIN automatic big gauge slitting line supplies many options, such as high speed slitting, medium speed slitting, etc. All slitters are easy to operate. They are very reliable, steady performers for both short and long terms running productions.

The thickness can range from the thinnest down to 1.0 mm, to the thickest up to 10mm

Strip Width, from the narrowest 400 mm to the widest 2200 mm

Coils Weight, up to 35 tons

Line Speed, up to 100 m/min.

Operator Safety.

Highest Production Outcome

Ease of Operation and Maintenance

Working procedure:

In the beginning, the coil is loaded on the coil car by crane and brought to the uncoiler by operating the coil car. Coil car centralizes the coil with the uncoiler mandrel and the coil is mounted on the uncoiler. Mandrel is expanded. Snubber roll rotates the coil. Peeler breaks the straps and brings the pre end upto Pinch roll. The Pinch roll drives the coil end upto the slitter. Then its drive is disconnected. Slitter moves the slitted strips further. Slitted strips are threaded through loop table and drag tensioner into the recoiler drum. Recoiler winds one turn on loose coil.

Then drag tensioner and loop are put into operation. Slitter and recoiler run simultaneously in synchronization. As the coil build up, the recoiler rpm correspondingly goes down to keep desired constant line speed. This process goes on until the end of coil on uncoiler. The slitted coil is pushed on the exit coil car through a pusher plate operated by hydraulic cylinder. The side slitted scrap is wound on the scrap winder units provided on both sides of the slitter.

|

Model No. |

RS 1.0-6.0 |

RS 2.0-8.0 |

RS 3.0-10.0 |

|

|

Coil Material |

CR Coils , HR Coils, S.S Steel Coils, GI Coils , AL Coils, Copper Coils Picking Oil Coils |

|||

|

Coil Thickness |

1.0~6.0mm |

2.0~8.0mm |

3.0~10.0mm |

|

|

Line Speed |

0 ~ 110m / min |

0 ~ 50 / 80m / min |

0-30 / 50m / min |

|

|

Coil Weight |

≤30T (35T) |

≤30T (35T) |

≤30T (35T) |

|

|

Coil I.D |

Φ508, φ610, φ760mm |

Φ508, φ610, φ760mm |

φ508, φ610, φ760mm |

|

|

OD coil |

≤φ2200mm |

≤φ2200mm |

≤φ2200mm |

|

|

Strip Width |

≥30mm |

≥50mm |

≥70mm |

|

|

Number of Strip |

4~15 |

5~20 |

5~18 |

|

|

Slitting Accuracy |

± 0.3mm |

± 0.3mm |

± 0.3mm |

|

|

Blade shaft |

Ф260mm |

Ф280mm |

Ф300mm |

|

|

Electrical Control System |

PLC Automatic control |

PLC Automatic control |

PLC Automatic control |

|

Customized slitting lines for every different kind of metal strip and in all required dimensions would be available.

Main Technical Specifications

|

COIL/ROLL DETAILS |

Material |

HR, CR, SS, GI, PPGI, Copper |

|

Tensile Strength |

δb≤600Mpa, δS≤360Mpa |

|

|

Coil/Roll thickness |

1-10mm |

|

|

Steel Coil/Roll width |

500-2200(Max) |

|

|

Coil/Roll I.D |

Φ500-760 mm |

|

|

Coil/Roll O.D |

Φ2000mm(Max) |

|

|

Steel Coil/Roll Weight |

35T(Max) |

|

|

Slitter parameters |

knife pivot diameter |

Ф220 mm |

|

Knife pivot material |

40Cr |

|

|

Blades specification |

Φ220mmXφ360mmX20mm |

|

|

Blade material |

6CrW2Si |

|

|

Max slit quantity |

4 pcs (4mm) 20 pcs(1mm) |

|

|

Width precision |

≤±0.05mm |

|

|

Other parameters |

Power |

380V/50Hz/3Ph(Customized) |

|

Line speed |

0-80m / min |

|

|

Capacity |

360 KW |

|

|

Whole line Dimension |

45m(L)X10m(W) |

|

|

Line direction |

From right to left(Face to machine) |

|

|

Machine color |

Blue |

We have metal slitter machine for sale! Rishbin was founded in 1999. With almost twenty years development, now it becomes a leading professional supplier in the field of Metal Coil Processing Machinery industry, and exports its quality production line to the markets all over the world. We sincerely invite and welcome people from all around the world to invest and create more values together.

Contact : Chris Ho, 0510 85853379

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Medium Gauge Slitting Lines Search in a category : Equipment goods Search in a category : medium, slitting, gauge, lines |

Tuesday, February 17, 2026

Quantity : 100,000 pc

JBI is one of the leading professional screw suppliers in Taiwan and specialized in manufacturing screws, bolts, nuts, washers, fittings, springs, and other hardware. All our products are produced according to the IFI, DIN, ISO International standard specification. Our fasteners...

Jeng Bright International Corporation

- jbitwco

- 830 - Kaohsiung City

- +88 6 77 02 10 77

Tuesday, February 17, 2026

Quantity : 660

Item Name RESTAURANT CHAIR/ BANQUET CHAIR. Model No QP-397 Material + Frame: steel. + Backrest & seat: upholstery imitation leather Size Chair: 51x44.8x103 cm Frame Color Stainless steel/ gold/ cream white/ black Leather (cloth) color Any color, pattern...

Qui Phuc Company Limited

- Luck06

- 700000 - Ho Chi Minh

- +84 9 86 58 28 62

Tuesday, February 17, 2026

Quantity : Customers - Price : Negotiable

Aerona Beauty professional quality stainless steel nail nippers adds sleek sophistication to any beauty routine to snip in style with ultimate accuracy. The handles are calibrated with single & double spring action needing only the slightest pressure for smooth trimming and...

Aerona Beauty manufacturers of beauty care instruments

- aeronabeauty

- 51310 - Sialkot

- 923217106500