Manual Molding Silicone Rubber

Quantity : 8 tons per Price : USD 4.8~7.5 /KG

a. Applications of Manual Molding Silicone Rubber:

Manual Molding Silicone Rubberis mainly used for model design of manual mold, PVC plastic molds, cement products, low melting point alloy molds, alloy toys, plastic toys, electronics, handicrafts, stationery, large-scale sculpture, reproduction of cultural relic, shoe sole molds, pad printing allocation, Electronic equipment anti-vibration, etc.

b. Model Codes of Manual Molding Silicone Rubber:

HY-528# is applicable to make molds of smaller products and the production will be 2-3 pieces.

HY-540#, compared to other two types, for its moderate hardness and better quality & performance, its production will be 20-30 pieces.

HY-570# is applicable to large size products duplications and Electronic equipment anti-vibration.

c. Operation Instructions forManual Molding Silicone Rubber:

RTV-2 Manual Molding Silicone Rubberis a flowable liquid, and the quality has nothing to do with the color. It consists of two components. Part A is a flowable liquid silicone rubber, part B is the curing agent. Firstly, after your previous work of dealing with the original model, take some liquid silicone rubber , add 2%-3% curing agent of the amount of silicon, and mix them evenly. Then after vacuum-pumping the mixture, you can pour it into the mold frame. The silicone mold will cured in 2-3 hours.

Note: The time for vacuum-pumping should be less than 3—5 mins, otherwise, once the silicone rubber has cross-link reaction during vacuum zing, it will not be operated.

FAQ of manual molding silicone rubber:

How to prevent silicone manual molds getting sticky?

The main reason for this problem is that you do not handle the products or original molds well, and then you should deal with the original mold or products carefully before molding. Such as for the products with a complicated pattern or an unsmoothed surface, you should polish and clean the products after which it will be molded, then spray the release agent. Normally, the release agent can be Vaseline, detergent. Liquid wax Etc. In practical process, you can bush different release agent according to different material.

The second reason is that the operator pours the silicone into the mold when the mixture is mixed evenly, then the finish silicone mold will not cure and dry entirely.

Contact : Lucas Peng, +86 755 89212369

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Manual Molding Silicone Rubber Search in a category : Raw materials Search in a category : rubber, manual, molding, silicone |

Thursday, June 16, 2022

Quantity : 100

Logitech MK295 Silent Wireless Combo. Facteur de forme du clavier: Standard. Style de clavier: Droit. Interface de l'appareil: RF sans fil, Disposition des touches du clavier: QWERTZ, Utilisation recommandée: Bureau. Couleur du produit: Noir. Souris incluse Clavier Utilisation recommandée...

MaKant Europe GmbH & Co. KG

- 60386 - Frankfurt am Main

- +49 (69) 9 150 750 14

Friday, March 22, 2024

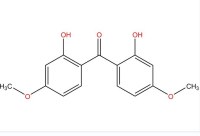

2,2-Dihydroxy-4,4-dimethoxybenzophenone PowerSorb™ 3049 is an efficient UV absorber for polyester film, which it protests from premature damage, particularly under severe exposure conditions. Technical Data of PowerSorb™ 3049 cas 131 54 4 Synonyms Uvinul 3049, Eversorb 52, UV-3049...

TinToll Performance Materials Co., Ltd.

- 225400 - Jiangsu

- 025 58599930

Wednesday, September 14, 2016

Quantity : 500 - Price : 50,00 €

Lift Check Valve DIN Standard Lift Check Valve DIN Lift check valve DIN Rückschlagventil mit innenliegender Schliessfeder DIN Válvulas de retención de tipo pistón DIN zpětný ventil DIN Standard tilbakeslagsventil med fjærbelastet kjegle DIN Standardında Kumandasız Çek Valf...

ETM Armaturen

- 59590 - Henri Durre

- 86 577 67953935