Magnetic Flux Leakage Testing Equipment

Quantity : 5000 units Price : 8-2 million

Electromagnetic detection is a very important non-destructive testing method and is widely used. Mag flux testing is a magnetic method of nondestructive testing that is used to detect corrosion and pitting in steel structures, most commonly pipelines and storage tanks.

The basic magnetic flux leakage principle is that a powerful magnet is used to magnetize the steel. When used in combination with other methods, it provides a quick and inexpensive assessment of the workpiece of ferromagnetic materials. With the advancement of technology, people are paying more and more attention to the automation of the inspection process. This not only reduces the labor intensity of the inspection work but also improves the reliability of the test results and reduces the influence of human factors.

The MFI magnetic flux leakage testing method is a highly automated magnetic flux testing technology. The magnetic flux leakage principle is that after the ferromagnetic material is magnetized, the surface and near-surface defects form a leakage magnetic field on the surface of the material, and defects are detected by detecting the leakage magnetic field. In this sense, the magnetic particle detection technology commonly used in pressure vessel inspection. However, it is customary to use the method of measuring the leakage flux with a sensor as the magnetic flux leakage ndt detection, and the magnetic flux to detect the leakage flux. The method is called magnetic particle detection and they are juxtaposed into two detection methods.

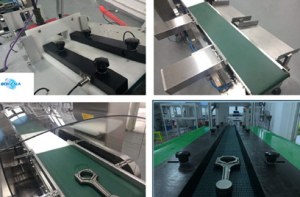

Portable Magnetic Flux Leakage Testing Equipment

Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near surface of the test piece.

Benchtop Magnetic Flux Leakage Testing Equipment

Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near surface of the test piece.

Magnetic particle testing can only detect surface and near-surface crack defects, and it needs surface grinding when testing. It is only suitable for the detection of workpiece discontinuation. In addition to the surface and near-surface crack defects, the MFI magnetic flux leakage inspection can also find the corrosion inside the workpiece from the outside. Defects such as pits, and do not need to be polished on the surface of the workpiece, suitable for on-line inspection of workpieces. On-line inspection of workpieces is currently the most urgent method for users, which can reduce unnecessary parking and reduce inspection costs. In addition, the magnetic flux leakage detection can also quantify the depth and length of defects. Although the application of magnetic flux leakage detection technology is rarely used in workpiece inspection, it has the advantages that magnetic particle detection does not have, so its application prospect is very broad.

As a non destructive testing equipment manufacturer and supplier, we have been committed to developing and manufacturing high-quality and high-performance NDT equipment to provide customers with the best quality service.

As one of the most professional mfl suppliers, BKN provides ndt testing machine, ndt testing, ndt ultrasonic testing equipment, ndt device, etc. Want to know magnetic flux leakage testing procedure or what is magnetic flux leakage? Please contact us.

Contact : Li Hui, +86 025 52244360

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Magnetic Flux Leakage Testing Equipment Search in a category : B2B Services Search in a category : testing, equipment, flux, leakage, magnetic |

Friday, April 03, 2015

Price : compétitif

Best canned sardines and mackerel from Morocco : high quality and good prices -High international quality standards. Our products are highly appreciated in the market ( regular orders after the first order ). - specifications : Box 125 gr Vegetable oil /Tomato oil/ chili oil...

maroc.pelagic

- 80000 - Agadir

- +212668440689

- +212 6 73 62 27 70

Saturday, June 06, 2015

Professional Prefabricated Steel Structure Warehouse: 1. General Description: Light steel structure building is a new type of building structure system, which is formed by the main steel framework linking up H-section, Z-section, and U-section steel components, roof and walls using...

Qingdao Forever Steel Structure Co., LTD

- xiaojia0217

- 266100 - qingdao

- 86 13730914607

- 86 532 68722363

Friday, May 30, 2014

Quantity : 100pieces - Price : 4000USD

giant inflatable pool / inflatable swimming pool / inflatable adult swimming pool 1.Best quality interesting inflatable slide for sale Material: 0.85mm PVC with SGS and EN71 certificate MOQ: one piece Size: can be customized Color: can be customized Package: ...

Zhengzhou Wolong Amusement Equipment Co., Ltd.

- sandycao

- 450000 - zhengzhou

- +13 6 73 71 16 52

- 86 371 62505511