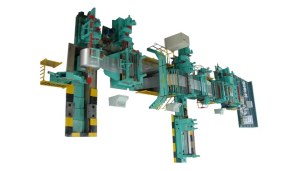

Light Gauge Slitting Lines

RISHBIN Light Gauge sheet metal slitter machine for pre-painted/coated coils, max. thickness of up to 3mm, max. width of up to 2200mm, and speed of up to 300 m/min. It consists of Decoiler with coil car, guiding & pinch device, high precision slitters, dual head/quick tooling change for slitter is available, scrap winder, side-guiding device, looping, tension device, recoiler. Different materials could be suitable to be processed in the metal slitter line, such as pre-painted steel coil, cold rolled steel coil, hot rolled carbon steel coil, stainless steel coil, copper, brass, aluminum and titanium. These products are for roll mill, HF tube mill, cold forming machines, punching & press machines etc.

To help you achieve your own production capacity target, RISHBIN Slitter supplies many options, such as high-speed slitting, medium speed slitting, sheet metal slitter machine, etc. All slitting line machines are easy to operate. They are very reliable, steady performers for both short and long terms running productions.

The thickness can range from the thinnest down to 0,10 mm, to the thickest up to 3 mm

Strip Width, from the narrowest 400 mm to the widest 2200 mm

Coils Weight, up to 30 tons

Line Speed, up to 300 m/min.

Operator Safety.

Highest Production Outcome

Ease of Operation and Maintenance

Working procedure of Light Gauge Slitting Lines

In the beginning, the coil is loaded on the coil car by crane and brought to the uncoiler by operating the coil car. Coil car centralizes the coil with the uncoiler mandrel and the coil is mounted on the uncoiler. Mandrel is expanded. Snubber roll rotates the coil. Peeler breaks the straps and brings the pre end upto Pinch roll. The Pinch roll drives the coil end upto the slitter. Then its drive is disconnected. Slitter moves the slitted strips further. Slitted strips are threaded through loop table and drag tensioner into the recoiler drum. Recoiler winds one turn on loose coil.

Then drag tensioner and loop are put into operation. Slitter and recoiler run simultaneously in synchronization. As the coil build up, the recoiler rpm correspondingly goes down to keep desired constant line speed. This process goes on until the end of coil on uncoiler. The slitted coil is pushed on the exit coil car through a pusher plate operated by hydraulic cylinder. The side slitted scrap is wound on the scrap winder units provided on both sides of the slitter.

Contact : Chris Ho, 0510 85853379

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Light Gauge Slitting Lines Search in a category : B2B Services Search in a category : light, slitting, gauge, lines |

Saturday, July 18, 2015

Specifications: Sheet Size: 210mm x 297mm, International A4 Quality: 100% imported virgin wood pulp Whiteness = 102-104%, Natural White Capacity: High speed Copying100ppm, Laser Capable, jet Specifications: Sheet Size: 210mm x 297mm, International A4 Quality: 100% virgin...

PAPERY (THAILAND )CO LTD

- 10400 - Bangkok

- 098765443533

Thursday, August 06, 2015

Quantity : 30 sets

The X. Y& Z axis utilizes AC servo motor. Multi-cavities machining, ORBIT-CUT machining & Helix machining. A.T.C. (Automatic Tool change) & C-axis machining available. The Circle Angle of Sparking is lower than 0.02mm. The best surface roughness (Ra) is better than 0...

Sane Kuei Machinery Co., Ltd

- Sane Kuei Machinery Co., Ltd

- 24158 - New Taipei City

- +886285112370

Tuesday, March 03, 2026

Automatic Gear Pump Liquid Filling Machine FP-465 is designed and engineered to produce outstanding quality and precision filling suitable for various products like shampoo, hot sauce, lubricant oil etc. FP-465 can also replace piston or peristaltic module for the flexibility of filling demands...

Autopack Co.,Ltd

- autopacker

- 33454 - Taoyuan City

- +88 6 33 68 98 06