Insert Molding

As a reliable precision quality machining & metalworks inc, Premium has more than 21 years' experience of precision machining service. We are good at providing customers with a cost-effective price, qualified precision machined parts, short lead time with better services. We've gained much more customer's trust and fulfilling their expectations from different projects by our fast, stable, accurate, objective, and professional attitude.we also provide die casting and plastic injection molding service.

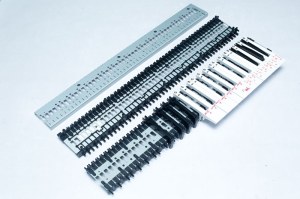

Premium provides insert molding service, which is a insert injection molding process that requires an insert to be pre-placed in the mold for injected plastic to flow around.

Plastic insert molding is ideal for improving the strength and reliability of a component by eliminating the need for secondary operations such as soldering, connectors, and adhesives. Insert molding can be accomplished through manual insert loading, the general cost-effective way to approach low volume applications or extremely complex part geometries, but automatic insert molding is a better choice for part consistency. It reduces human error, improves efficiencies, and ensures optimal cycle times.

How Does Insert Molding Work?

Insert molding can be processed both vertical and horizontal molding machines:

1. The inserts are loaded into the custom mold manually or robotically.

2. Molten plastic is injected into the mold.

3. The mold opens once cooling and the components are removed.

- Components are separated from the sprue and inspected.

Advantages and Disadvantages of Insert Molding

|

Advantages |

Reduced size and weight |

|

Save assembly costs |

|

|

Enhanced design flexibility |

|

|

Improved component reliability |

|

|

Improved part strength and durability |

|

|

Disadvantages |

Higher unit pricing |

|

High defective rate |

Application for Insert Molding

Industry:

Medical

Automotive

Consumer products

Electronic components

&More

Common applications:

Electronic housings

Knobs

Dials

hand-held devices

We also provide metal insert plastic injection molding , metal insert molding, insert injection molding and so on.

Contact : Wang Twinkle, 86 0755 2729 8551

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Insert Molding Search in a category : B2B Services Search in a category : molding, insert |

Friday, November 21, 2014

Quantity : 1 UNIT - Price : 1,5 USD

We have been manufacturing PAINT ROLLERS for 10 years in our factories in Konya and Istanbul. Our PAINT ROLLERS are categorized in 3 types depending on application that all can be used for both Water Based Paints and Solvent Based Paints : • PAINT ROLLER for EXTERIOR FACADES. Lengths ...

TURKON EXPORT LTD.

- 42050 - KONYA

- +905353265862

Tuesday, February 17, 2026

Quantity : 50

- Pneumatic Hot Foil Date Coding Machine - - Model No.: PE-300 - The essential characters of Pneumatic Hot Stamping Date Coder PE-300 are high speed ( up to 120 prints/min ), small volume and can be easily installed on VFFS and intermittent packaging machines. It is for coding manufacturing...

Autopack Co.,Ltd

- autopacker

- 33454 - Taoyuan City

- +88 6 33 68 98 06

Tuesday, February 17, 2026

Quantity : 10.000 - Price : 1500 a 1600$mt

We are able to supply the best quality frozen food products worldwide. Our prices are very competitive and are the best you can find. We spend our time in understanding our customers need and we have the skills and ability to meet every customer's specific requirement. With a skill...

IRAN Trade

- ogfrance

- 93201 - Tehran

- +33 7 62 58 79 19