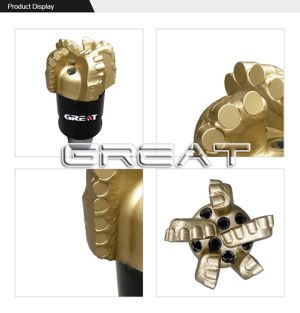

Hard Rock PDC cone bit Used for drill underground core

Price : 1000-6000USD

Overview of PDC Core Bit

GREAT customized made Diamond core bits, which include Matrix body PDC bit and Steel body PDC bit, the Diamond core bit is used to drill an underground core (or mineral core) primarily when samples of underground rock (minerals) are required.

Every PDC Core bit is optimized hydraulically for each cutting structure and formation application.

Each design is based on a balanced and fully covered cutting structure.

Sometimes we need to analyze the rock, so the best choice is to consult GREAT, one of the most trusted drill bit manufacturers in china, to get your right recommendation.

The Details of PDC Core Bit

The Specification of PDC Core Bit

|

Bit Size and Type |

8 1/2"GMC3232 |

Nozzle Qty |

12P |

|

Cutter Size (mm) |

Φ13mm ×30 |

Gauge Lenghth |

1.8" |

|

Blade |

12 |

Connection |

Chuan 7-4 |

|

Operating Parameters |

|||

|

Rotary Speed(rpm) |

40~150 |

Weight on Bit(KN) |

40~80 |

|

Max.WOB(KN) |

90 |

Flow Rate(lps) |

10~30 |

The Advantage of PDC Core Bit

The PDC Core bit has designed a shallow parabolic profile and medium cutter density for coring the medium hard formation. Nozzles options according to the hydraulic request, it is installing the size of the mainly PDC cutter is 1308mm, and the most popular blade is 6 blades, 7 blades, 8 blades, to enhance the rock hammer drill bits' ability to drill in hard formations. Special TSP gauge or PDC Arc-cutters to protect the diameter.

The superior patented tool testing method provides the best PDC cutter for any challenge.

Soft to medium-hard formation with low compressive strength interbedded with hard layers.

Cab be used for different rock types: Mudstone, limestone, anhydrite.

Application of PDC Core Bit

Polycrystalline Diamond Composite (PDC) core bits were originally designed for oil drilling. The surface of the cylindrical PDC cutters consists of high-quality synthetic diamond particles sintered together by high pressure and temperature. The PDC core bits have high tool hardness, wear resistance and toughness, and the bits are widely used in oil, gas, mining and engineering drilling fields.

PDC core bits are ideally suited for use with high power drilling rigs operating at relatively low speeds, and offer much better drilling life and than surface fixed bits.

Cangzhou Great Drill Bits Co.,Ltd. is a drill bit manufacturers, we have roller cone bits for sale, rotary hammer drill bits for rock, and out quality and service is trustworthy. Welcome to know more about us and purchase our products.

Contact : Wang Weiwei, +86 13161769999

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Hard Rock PDC cone bit Used for drill underground core Search in a category : Everything else / Bulk Search in a category : cone, rock, hard, underground, drill, core |

Saturday, July 19, 2014

Cool White LED with color temperature 7000K to 7500K implies a mild blue tint in the white glow. Cool White is preferred in many applications because the light they output makes items illuminated appear crisper. Cool White is often preferred in bathrooms and other task areas. Note...

Real Green lighting Company

- Bonny Chan

- 529000 - Jiangmen City

- +15 6 02 20 39 93

Sunday, March 15, 2015

TAYSAN MAKINA CO. SARL. Is a company that makes the production of types R fullyautomatic and manual machines for making hard sugar cubed Turkey and alsomachines to various food packaging and sugar cubes since ten years experience. With its quality and his professional crew gives...

Taysan Makina Ltd

- taysanmakina

- 06370 - Ankara

- 0090 312 396 01 09

- 0090 546 610 06 05

Wednesday, January 13, 2016

Established in 2000, Focus CNC Co., Ltd. provides series of CNC Lathe Machinery, CNC Lathe, live tool CNC Lathe, mill turn Lathe and CNC turning machine. Due to our principle of “Humanity, Technology and Precision” in mind, we keep breaking through to become one leading Industry...

Focus CNC Co., Ltd.

- focus.cnc1999

- 428 - Taichung City

- +886 4 2560 6067