Flange Molding

Flanged joint is the main connection method in pipeline construction. Compared to thermoplastic, thermoset composite can be reprocessed. With high insulating properties, Insulated flange is widely applied in petroleum and chemical and other industries. Flange molding is injection and pressure molded, delivering consistent quality.

Advantages of SMC/BMC Flanges

Insulation property required by buried pipeline

Long-term stable performance under hard conditions

High strength and airtightness

Simple structure, easy to assembly, dismount and change parts

Corrosion free

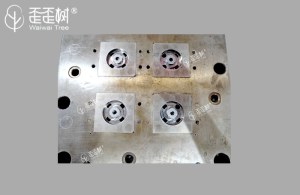

SMC Flange Moulding

Reduce human factor to a minimum in production

Compression molding shortens the delivery time and produce constant quality

Well-suited for mass production of small diameter flanges

Flange Molding Surface Treatment

Outer surface is smooth and precise, needing no machining.

Interior surface can be machined according to requirements.

Flange Molding Specifications

|

Material |

Based on requirements |

|

Color |

Custom and depending on requirements |

|

Pressure rating |

custom |

|

Operation Temperature |

Depending on molding |

Aobang provide bmc composite, bmc compound, automotive smc moulding and etc. Contact us to know bulk molding compound process or more.

Contact : Li Coffee, +86 15657163173

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Flange Molding Search in a category : Everything else / Bulk Search in a category : molding, flange |

Wednesday, April 22, 2015

Quantity : 1piece - Price : USD5~36

1 Ashiloy Industry co,ltd solar panel: 3W 2 Lithium Battery: 3.7V / 4400mA high quality full capacity battery. 3.LED: power 3W, 38pcs. Epistar SMD 2835LED , color temperature 5500-6000K, lumens about 300LM. Brightness equivalent to 12 watts of brightness tricolor energy-saving...

Ashiloy Industry Co.,Ltd

- 999077 - KLN

- +86 138235618632

Friday, December 15, 2017

OEM PART NO DESCRİPİTİON 66072 Crown Wheel and Pinion FOR CARRARO 13X30 66941 Crown Wheel and Pinion 15x37 2277448 CATERPİLLAR AİR FİLTER OUTER 2277449 CATERPİLLAR AİR FİLTER İNNER 01/117901 FAN BELT 01/124403 FAN BELT 01/124404 02/100073 Oil Filter Canister Type, MEDİUM MODEL 02/100284...

ANAC MAKINA CO LTD STI

- 34800 - İSTANBUL

- +905069691531

- +9005069691531

Thursday, August 06, 2015

Quantity : 30 sets

The X. Y& Z axis utilizes AC servo motor. Multi-cavities machining, ORBIT-CUT machining & Helix machining. A.T.C. (Automatic Tool change) & C-axis machining available. The Circle Angle of Sparking is lower than 0.02mm. The best surface roughness (Ra) is better than 0...

Sane Kuei Machinery Co., Ltd

- Sane Kuei Machinery Co., Ltd

- 24158 - New Taipei City

- +886285112370