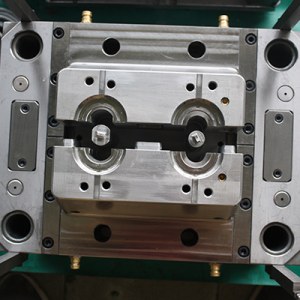

Family Mould

What is the family mold?

A mold that can only produce one product at a time is called a single-cavity injection mold. If a mould is used to produce two or more plastic parts at a time, multi-cavity injection, if the parts are different, such a mold is called family mold.

The plastic parts produced by the single cavity mold have high precision, easy control of process parameters, simple mold structure, low mold manufacturing cost and short cycle time. However, the productivity of plastic molding is low, and the cost of plastic parts is high, which is suitable for large plastic parts, high precision requirements or small batches and trial production.

The plastic parts produced by the multi-cavity mold or family tool injection molding have low precision, it is difficult to control the process parameters, the mold structure is relatively complicated, the mold cost is high, and the cycle time is longer. However, productivity is higher, the cost of plastic parts is lower, and it is suitable for large quantities and long-term production of small-sized plastic parts.

The number of cavities is often determined by factors such as budget, clamping force, plastic part structure, and injection volume.

When designing a multi-cavity mold, one method is to determine the model of the injection molding machine, and then calculate the number of cavities according to the technical parameters of the injection molding machine and the technical requirements of the plastic parts; the other method is based on the requirements for production efficiency and the structure of the part require the number of cavities to be determined, and then choose the proper injection molding machine or check the existing injection molding machine.

We normally make the multi-cavity mold with 2 cavities, 4 cavities, 8 cavities, 16 cavities, 32 cavities, 48 cavities, etc. For family mold, we normally make at 1+1 cavities, 2+2 cavities, 4+4 cavities, 8+8 cavities, we can find the numbers are always double. Family mold help to molding different plastic parts in the same mould, this solution saves tooling and molding cost. For most family mold, the plastic part is in the same material & similar size, HanKing Mould will help customers to analyze the possibility to make the best economic plastic injection mould.

Contact : Yoyo Tang, 86 13798257041

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Family Mould Search in a category : Clothes Search in a category : mould, family |

Saturday, June 27, 2015

Quantity : 200 - Price : 0,75 €

Bonjour, A la vente, cable de recharge d'un métre avec port USB pour téléphone Samsung/Android. 0.95€/pièce pour un carton de 100. 0.75€/pièce pour un carton de 200. Possibilité de faire un total de 200 avec cable Iphone et Samsung. ( je suis AE, donc pas de TVA) Livraison possible...

Hard Discount 93

- 93420 - Villepinte

- 06 52 93 24 09

Friday, October 02, 2015

Quantity : 25000 - Price : 1 EURO

Bonjour , je destocke un lot qui peut être fragmenter et vendu séparément d'accessoires en téléphonie mobile à savoir : Produits neufs sur Apple , Blackberry ,Samsung , Nokia , wiko , Htc... Batteries de toutes marques , coques et housses de marques et no name sur Smartphones et tablettes ...

SO-TRADE

- 13008 - MARSEILLE

- +33 6 64 93 20 67

Saturday, August 22, 2015

NOUS SOMMES UNE SOCIETE MAROCAINNE CHINOISE INSTALEE AU MAROC. ON PEUT VOUS FAIRE VOTRE PROPRE MARQUE DU THE VERT.NOIR ET Tisanes médicinales : +Thé contre les Gaz et les Fermentations. +Thé contre la digestion lente, et l'acidité. +Thé Laxative, contre la constipation. +Thé Calmante...

SUDMARKET

- 20000 - CASABLANCA

- +21 2 60 69 94 40

- 00212668166018