Electronic potting compound silicone rubber

Quantity : 200KG Price : USD7.58

Electronic potting compound silicone rubber

Typical Application of Electronic potting compound silicone rubber:

Electronic potting compound silicone rubber is suitable for bonded seal of electronic components, po wer module and control module, which requires waterproof and insulation. It can be broadly used for LED screen, Wind Power Generator, PCB substrate, etc.

Description of Electronic potting compound silicone rubber:

Electronic potting compound silicone rubber,liquid silicone

is a newly insulating material silicon of silicon compounds.

It cures without heat, corrosion and just with little shrinkage. It can be applied to the sealing an d pouring of various electronic components, and then forming insulation system.

Features of Electronic potting compound silicone rubber:

1. No toxicity, solventless, no odor and no cure by-product.

2. Equal amount of mixing ratio, good fluidity, easy processing.

3. No significant exotherm or shrinkage during curing.

4. Flexible curing schedule, can be cured at room temperature (R.T.) or at elevated temperature.

5. Very stable to changes of temperature, stability over wide temperature range (-50 to 200 oC).

6. Good fire resistance, UL94V0 approval.

7. Excellent thermal conductivity.

8. Excellent dielectric properties for maintaining and protection of existing electrical insulation requirements.

9. Excellent weather resistance and waterproof property for protection from moisture and dust contam ination.

10.Relative easier removal benefits to repair of electrical/electronic devices.

Technical Parameters of Electronic potting compound silicone rubber:

|

Before Curing |

Appearence |

Black/Transparent Fluid |

|

Density(25°C g/ml) |

0.98±0.02 |

|

|

Viscosisty(25°Ccps) |

Part A 500±100: Part B: 800±100 |

|

|

Mixing Ratio |

A: B=1: 1(By weight) |

|

|

Operating Time(25°C hr) |

5 |

|

|

Curing time(80°C hr) |

0.5 |

|

|

After Curing |

Hardness(Shore A) |

0-40 |

|

Dielectric Strength(KV/mm) |

23 |

|

|

Volume Resistance(Ω.Cm) |

1.0×10 15 |

|

|

Permittivity(1.2MHz) |

3.0 |

|

|

Temperature Resistence(°C) |

-60~200 |

|

|

Fire Resistance |

UL94-V1 |

Precaution of Electronic potting compound silicone rubber:

1. Twelve(12) months when stored at 24C in tightly closed original packages.

2. This kind of product is non-dangerous product, which could be transported as general chemicals.</ p>

3. Storage beyond the expired date doesnot necessarily mean that the product is no longer usable. In this case however, the properties required for the intended use must be checked for quality assuran ce reasons

Operation way of Electronic potting compound silicone rubber:

1.Put part A and part B in separate container with equal dosage and stir evenly when mixing the two parts together.

2. Put the mixture into the vacuum machine under 0.08 MPa for 5 minutes.

3. The temperature influences the curing time of electronic potting silicone rubber. When in too low temperature, we suggest customers appropriately heat the mixture to accelerate vulcanization.

Package of Electronic potting compound silicone rubber:

20Kg/pail (Part A10Kg + Part B10Kg)

Need any help on silicone rubber, please feel free to contact Ms Kitty:

Tel: 86-755-89212369

Mob: 86-18938867593

E-mail: hyjz(at)szrl(dot)net

Skype: kity-467707861

Contact : kity huang, 8675589948294

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Electronic potting compound silicone rubber Search in a category : Raw materials Search in a category : rubber, compound, silicone, electronic, potting |

Thursday, June 16, 2022

Quantity : 100

Concentrez-vous sur votre travail et éliminez les distractions. Découvrez l'ensemble sans fil silencieux MK295 doté de SilentTouch, une technologie exclusive de Logitech qui élimine plus de 90 % des bruits du clavier et de la souris. Vous bénéficiez de la même sensation de frappe...

MaKant Europe GmbH & Co. KG

- 60386 - Frankfurt am Main

- +49 (69) 9 150 750 14

Friday, March 22, 2024

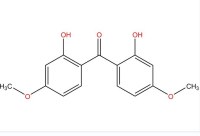

2,2-Dihydroxy-4,4-dimethoxybenzophenone PowerSorb™ 3049 is an efficient UV absorber for polyester film, which it protests from premature damage, particularly under severe exposure conditions. Technical Data of PowerSorb™ 3049 cas 131 54 4 Synonyms Uvinul 3049, Eversorb 52, UV-3049...

TinToll Performance Materials Co., Ltd.

- 225400 - Jiangsu

- 025 58599930

Thursday, June 16, 2022

Quantity : 100

Logitech Bluetooth Slim Folio iPad Pro 12.9" 3./4.Gen Noir représentation / réalisation Compatibilité de marque Apple Compatibilité iPad Pro 12.9-inch (3rd generation), (Model: A1876, A1895, A1983, A2014), iPad Pro 12.9-inch (4th generation) Couleur du produit Graphite Taille maximum...

MaKant Europe GmbH & Co. KG

- 60386 - Frankfurt am Main

- +49 (69) 9 150 750 14