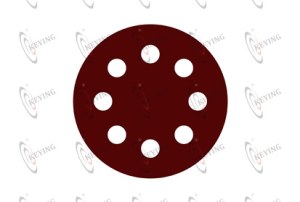

CORSE GRINDING

Coarse Grinding can improve grinding efficiency and reduce abrasive wear. It has the functions of protecting and lubricating the workpiece, deburring, flashing, rounding, removing scale, removing rust and strengthening the metal surface of the workpiece, and leaving a balanced allowance for fine grinding. Make the size of the finely ground stable and better.

Features Of Corse Grinding

Most application of coarse grinding is from heavy stock removal to rough blending, heavy coating, rust removeal, shaping and sharpening , welding treatment, flaws, cracks, risers and painting lines, paint, weld seams removal; edge chamfering and deburring;

It is mainly used to remove burrs, scratches, rust marks, oxide scale, sand holes, bubbles, weld beading, welding and various macro defects on the surface of parts, so as to improve the surface flatness and reduce the surface roughness. The workpiece surface after rough polishing can only reach the level of flatness and smoothness, and can not get a bright surface.

Applications Of Corse Grinding

1

Most application of coarse grinding is from heavy stock removal to rough blending, heavy coating,rust removeal, shaping and sharpening, welding treatment, flaws, cracks, risers and painting lines, paint, weld seams removal; edge chamfering and deburring.

2

It is mainly used to remove burrs, scratches, rust marks, oxide scale, sand holes, bubbles, weld beading, welding and various macro defects on the surface of parts, so as to improve the surface flatness and reduce the surface roughness. The workpiece surface after rough polishing can only reach the level of flatness and smoothness, and can not get a bright surface.

We can offer types of grinding stones for sale, if you have needs to buy grinding stone for stainless steel, please leave us a message.

If you want to know more about how to grind steel, please visit our website.

If you are looking for a reliable abrasives supplier, please contact us, and we will be your best partner.

Keying is always focusing on the manufacture and supply quality advanced abrasive and grinding tools, including various series of abrasive tools, like mounted round flap wheel with shaft, miniature unmounted flap wheels, flap discs, non-woven grinding and polishing wheels/discs, wool felt polishing wheels, mounted points and other abrasive tools.

Contact : com keyingabrasives, +86(0)576 86711667

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of CORSE GRINDING Search in a category : B2B Services Search in a category : corse, grinding |

Thursday, August 06, 2015

Quantity : 30 sets

The X. Y& Z axis utilizes AC servo motor. Multi-cavities machining, ORBIT-CUT machining & Helix machining. A.T.C. (Automatic Tool change) & C-axis machining available. The Circle Angle of Sparking is lower than 0.02mm. The best surface roughness (Ra) is better than 0...

Sane Kuei Machinery Co., Ltd

- Sane Kuei Machinery Co., Ltd

- 24158 - New Taipei City

- +886285112370

Wednesday, April 15, 2015

Quantity : Inquiry - Price : USD 0.8-1.5/piecs

Dimensions : 156mm x 156mm ± 0.5mm. Thickness (Si): 180μm ± 20μm / 200μm ± 20μm. Front : Silver bus bars Silicon nitride anti-reflection coating. Back : Silver bus bars Full-surface aluminum BSF. Location : 5F,No.2.Sec.4.JhongyangRd,TuchengCity.Ta ipei County 236,Taiwan R.O.C,...

Taiwan

- 23678 - New Taiwan City

- +886 2 22691686

Friday, May 16, 2014

Quantity : 500000pcs - Price : $1-25/pc

Prototype Description SLA and SLS Why Use Stereolithography? Stereolithography is very similar to the SLS(Selective Laser Sintering) prototyping process.It's best to use SLA,when surface finish and overall appearance straight from the machine is the most important factor in the prototype...

Xiamen Karo Co.,Ltd

- karoplastic

- 361002 - Xiamen

- 0086 592 5135406