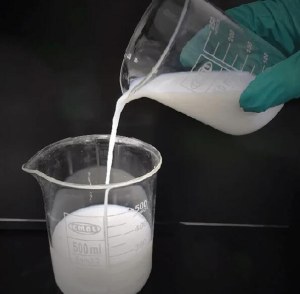

A-Plane Sapphire Colloidal Silica

Kona series Sapphire Polishing Slurry developed for kinds of Sapphire products, such as sapphire lens and sapphire substrate. Our colloidal silica polishing provide a good surface finish with no compromise with polish rate, and alumina slurry especially suitable for C-plane sapphire with a fast removal rate and controlled surface finish.

A-PLANE SAPPHIRE COLLOIDAL SILICA FEATURES

According to the characteristics of the CMP process of sapphire processing, we developed water-based alkaline PH Colloidal Silica.

Kona Sapphire Colloidal Silica especially developed for Sapphire, with increased abrasive particle size, which can improve the removal rate as well as no compromise with high quality surface.

Sapphire Substrate is a kind of extremely hard semiconductor substrates, Kona engineering developed Sphere Substrate Polishing Slurry, including colloidal silica and alumina slurry.

In most cases, diamond abrasives is used for sapphire grading. However, which leaves scratches and other strains on the sapphire surface. So sapphire substrates need to be polished use colloidal silica or alumina slurry.

A-PLANE SAPPHIRE COLLOIDAL SILICA APPLICATIONS

Because of its good hardness and light transmittance, A-plane sapphire is widely used in various window materials, such as the transparent cover of watch and various medical Windows. Lapping and polishing processing to A-Plane sapphire is difficult, must choose the appropriate polishing slurry for polishing, otherwise it is really hard to polish the a-plane sapphire surface.

Kona provide nano alkaline silica colloidal for A-Plane sapphire polishing.

Contact : Kona Kona, +18 3 90 90 84 73

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of A-Plane Sapphire Colloidal Silica Search in a category : Medical Search in a category : colloidal, silica, plane, sapphire |

Friday, May 16, 2014

Quantity : 500000pcs - Price : $1-25/pc

Prototype Description SLA and SLS Why Use Stereolithography? Stereolithography is very similar to the SLS(Selective Laser Sintering) prototyping process.It's best to use SLA,when surface finish and overall appearance straight from the machine is the most important factor in the prototype...

Xiamen Karo Co.,Ltd

- karoplastic

- 361002 - Xiamen

- 0086 592 5135406

Friday, May 16, 2014

Quantity : 50000pcs - Price : $1-25/pc

Prototype Description SLA and SLS Why Use Stereolithography? Stereolithography is very similar to the SLS(Selective Laser Sintering) prototyping process.It's best to use SLA,when surface finish and overall appearance straight from the machine is the most important factor in the prototype...

Xiamen Karo Co.,Ltd

- karoplastic

- 361002 - Xiamen

- 0086 592 5135406

Friday, May 16, 2014

Quantity : 500000pcs - Price : $1-25/pc

Prototype Description SLA and SLS Why Use Stereolithography? Stereolithography is very similar to the SLS(Selective Laser Sintering) prototyping process.It's best to use SLA,when surface finish and overall appearance straight from the machine is the most important factor in the prototype...

Xiamen Karo Co.,Ltd

- karoplastic

- 361002 - Xiamen

- 0086 592 5135406