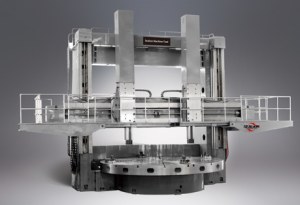

2-Axis CNC Double Column Vertical Lathe

CNC lathe 2 axis Double Column Vertical Lathe is compatible with automatic tool change system (ATC) and ATC as well as complex machining functions. Regarding the column heightening model, there is a double sliding column system. The cross beam of 2 axis lathe can move up and down to achieve better cutting accuracy. Users can choose one to match their own processing needs.

Application Fields of 2-Axis CNC Double Column Vertical Lathe

Energy

Earth Moving

Die&Mold

General Machining

Features

Features of 2-Axis CNC Double Column Vertical Lathe

Double column vertical lathe is designed with hydrostatic bearings for better cutting performance. It is equipped with a variety of modern features and is best suited to the manufacturer's processing requirements. The machine is compatible with the automatic tool change system (ATC) and ATC as well as complex machining functions. Regarding the column heightening model, there is a double sliding column system. The cross beam can move up and down to achieve better cutting accuracy. Users can choose to match their own processing needs.

With those models, cnc machine tools suppliers can use advanced cnc machine tools to assist in better processing. The double column vertical lathes are capable of handling different types of tasks to meet a wide range of machining requirements.

The heavy-duty spindle incorporates a high precision hydrostatic bearing designed to withstand high axial and radial loads. In the hydrostatic system, pockets of oil between the base of the machine and the table eliminate contact between mating surfaces and promote friction-free operation. The combination of the high/low motor and 2-speed gearbox provides the benefits of a 3-speed transmission. Power is transmitted through a Class 1 ring and pinion gear that provides a further gear reduction and torque multiplication.

The X and Z axes are a box way design that facilitates heavy-duty machining and high precision. The Turcite B-coated ways are completely enclosed and feature a forced lubrication system. The rigid twin column design and heavy base are best castings, heavily ribbed to minimize thermal distortion and dampen vibration.

Advantages

Advantages of 2-Axis lathe machine

The machine is suitable for rough or fine machining of auto, bearing, wind power, motor, and water pump, etc.

The base and column use one-piece high-quality castings.

X&Z is using a brand linear guideway.

The main transmission is driven by frequency or a servo motor, simple structure, and high transmission efficiency.

Servo motor and gearbox directly drive the Ballscrew for X&Z axis feeding. It can reach high accuracy and fast-moving.

The machine can equip an optical ruler to realize full close loop control.

Full cover is your optional together with a chip conveyor and coolant system.

Siemens or Fanuc system.

Parameters

Parameters of 2-Axis CNC Double Column Vertical Lathe

|

Model No |

C5820 |

C5225 |

C5240 |

C5250 |

C5263 |

C5280 |

|

Max Machining Diameter(mm) |

2,000 |

2,500 |

4,000 |

5,000 |

6,300 |

8,000 |

|

Max Machining Height(mm) |

1,400 |

1,600 |

1,600 |

2,000 |

2,500 |

3,000 |

|

Max Load on Table(Kg) |

6,300 |

10,000 |

15,000 |

32,000 |

63,000 |

100,000 |

|

Table Diameter(mm) |

1,800 |

2,250 |

3,500 |

4,200 |

5,800 |

6,300 |

|

Main Motor Power(Kw) |

55 |

55 |

75 |

75 |

110 |

130 |

|

Table Rotary Speed(r/min) |

2.5-80 |

2-63 |

2-40 |

1-35 |

0.34-25 |

0.25-25 |

|

Horizontal Travel X(mm) |

1,300 |

1,400 |

2,200 |

2,700 |

3,950 |

4,450 |

|

Vertical Travel Z(mm) |

1,350 |

1,000 |

1,000 |

1,250 |

1,600 |

2,000 |

|

Feeding Speed of X&Z(mm/min) |

1-2,000 |

1-2,000 |

1-2,000 |

1-3,000 |

1-3,000 |

1-3,000 |

|

Position Accuacy of X&Z(mm/1000mm) |

+/-0.03 |

+/-0.03 |

+/-0.03 |

+/-0.03 |

+/-0.03 |

+/-0.03 |

|

Size of Machine LxWxH (M) |

3.7x3.6x4.9 |

5.4x4.6x4.9 |

6.8x5.0x5.0 |

8.4x6.3x5.5 |

14.2x7.2x9.2 |

15.7x8.7x9 |

|

Weight of Machine (Kg) |

25,000 |

35,000 |

50,000 |

80,000 |

180,000 |

260,000 |

Configuration List

Configuration List of 2-Axis CNC Double Column Vertical Lathe

Siemens/Fanuc System

Electric Tool Post

A/C for Electric Box

Threading

Servo Main Motor

Full Cover with Chip Conveyor

ATC System

Inquiry Form

Recommended Vertical Lathe

Machine Tool Technology Applied

01

Hydrostatic Rotary Table

02

Thermo Friendly

03

DVT Mode

04

Operator Productivity

05

Cutting Performance

News Room

Contact : Steven Liu, 021 57880511

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of 2-Axis CNC Double Column Vertical Lathe Search in a category : Everything else / Bulk Search in a category : lathe, column, double, axis, vertical |

Saturday, November 15, 2014

As owner, we have for sale : * Man-Roland R 304 HOB+LV (P), Year 1999 53x74 - 4 Colors + Coating Tower with Anilox "Chambered Doctor Blade" + Extended Delivery Equipped with: RCI 2 Console CCI with ColorPilot Grapho Metronic CPL (Semi-Automatic Plate Change) Automatic Paper...

ACS DIFFUSION s.a.s.

- acsdiffusionsa

- 42952 - Saint-Etienne

- 0033 (0)4 77 92 77 88

- 06 10 63 37 83

Wednesday, August 05, 2015

As owner, we have for sale this nice machine as: * Heidelberg SM74-5-H SE, Year 2004 52x74 - 5 Colors - SE Model, Speed 13.000 sph Equipped with : . CP 2000 PrintCenter . Autoplate . Preset . All Automatic Washers Devices : Blanket / Impressions Cylinders & Inking Rollers ...

ACS DIFFUSION s.a.s.

- acsdiffusionsa

- 42952 - Saint-Etienne

- 0033 (0)4 77 92 77 88

- 06 10 63 37 83

Friday, May 23, 2014

Quantity : 2 - Price : 850,00 €

Used refrigerated buffet state I have two rooms available (identical) equipped roulette static cooling system for more information: gas CE compliant VAT price, except areas Europe (EU VAT) for more information: M.C.FRANCE SAS Street expectancy 75 59100 Roubaix TEL: 09...

MCFRANCE SAS

- 59200 - Tourcoing

- 07 81 55 30 28

- 06 51 11 02 96