Seller haoye

Report abuse

| haoye | |

|

|

Details |

|

Rating profile : 3.7/5 Number of received votes : 0 |

|

Member since 21 February 2017 Place where the seller is located : zhengzhou See this display haoye |

silicon carbide rod is made of high purity green hexagonal silicon carbide as the main raw material, according to a certain ratio of processing blanks, the 2200 ℃ high temperature silicification recrystallization sintering and made of rod-shaped, tubular high-temperature non-metallic heating element. oxidative atmosphere in the normal use of temperature up to 1450 ℃, continuous use of up to 2000 hours. high temperature, high temperature resistance, oxidation resistance, corrosion resistance, fast heating, long life, high temperature deformation is small, easy installation and maintenance, and has good chemical stability. and automatic control system supporting, can be accurate constant temperature, but also according to the needs of the production process automatically thermostat curve. the use of silicon carbon rod heating is convenient, but also safe and reliable. now it has been widely used in high temperature fields such as electronics, magnetic materials, powder metallurgy, ceramics, glass, semiconductors, analytical laboratory and scientific research etc., and has become a leading supplier in tunnel kiln, roller kiln, glass furnace, vacuum furnace, muffle furnace and smelting furnace. various types of heating equipment, electric heating elements.

Tuesday, February 17, 2026

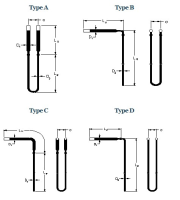

The Hao-M elements is a dense cermet material consisting of molybdenum disilicide(MoSi2) and a glassy phase silicon dioxide(SiO2). They can be operated at element temperatures up to 1800℃ in oxidizing atmosphere. The elements are U shaped and are most frequently used suspended with...

Zhengzhou Haoye HaoHeating elements Co.,Ltd

- haoye

- 450000 - zhengzhou

- 86 0371 63337760

- 86 13803824639

Saturday, March 04, 2017

Silicon carbide rod is made of high purity green hexagonal silicon carbide as the main raw material, according to a certain ratio of processing blanks, the 2200 ℃ high temperature silicification recrystallization sintering and made of rod-shaped, tubular high-temperature non-metallic...

Zhengzhou Haoye HaoHeating elements Co.,Ltd

- haoye

- 450000 - zhengzhou

- 86 0371 63337760

- 86 13803824639

Saturday, March 04, 2017

The Hao-M elements is a dense cermet material consisting of molybdenum disilicide(MoSi2) and a glassy phase silicon dioxide(SiO2). They can be operated at element temperatures up to 1800℃ in oxidizing atmosphere. The elements are U shaped and are most frequently used suspended with...

Zhengzhou Haoye HaoHeating elements Co.,Ltd

- haoye

- 450000 - zhengzhou

- 86 0371 63337760

- 86 13803824639

Saturday, March 04, 2017

The Hao-M elements is a dense cermet material consisting of molybdenum disilicide(MoSi2) and a glassy phase silicon dioxide(SiO2). They can be operated at element temperatures up to 1800℃ in oxidizing atmosphere. The elements are U shaped and are most frequently used suspended with...

Zhengzhou Haoye HaoHeating elements Co.,Ltd

- haoye

- 450000 - zhengzhou

- 86 0371 63337760

- 86 13803824639

Saturday, March 04, 2017

The Hao-M elements is a dense cermet material consisting of molybdenum disilicide(MoSi2) and a glassy phase silicon dioxide(SiO2). They can be operated at element temperatures up to 1800℃ in oxidizing atmosphere. The elements are U shaped and are most frequently used suspended with...

Zhengzhou Haoye HaoHeating elements Co.,Ltd

- haoye

- 450000 - zhengzhou

- 86 0371 63337760

- 86 13803824639