|

|||||||||||||||||||

|

Raw materials

HS 2343ESR-S Hot Work Die Steel

|

|

Steel Grade |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

V |

|

HS 2343ESR-S |

0.34-0.40 |

0.90-1.20 |

0.30-0.50 |

≤0.014 |

≤0.002 |

4.90-5.20 |

1.20-1.40 |

0.30-0.50 |

HS 2343 ESR-S (Material 1.2343 Equivalent) Applications

Plastic molds with a thickness of more than 400mm;

Auto lamp mold, automobile bumper, and dashboard mold, etc.

HS 2343 ESR-S (1.2343 Steel Equivalent Material) Features

Electroslag remelting, high-temperature diffusion annealing and ultra-fine heat treatment are applied, and make good structure uniformity and finely dispersed carbides;

Good heat and cold fatigue resistance and corrosion resistance, good cold and hot processing performance, high toughness and wear resistance;

High purity control brings high polishability;

High isotropy, aspect ratio ≥0.85;

Annealing hardness ≤200HB, quenching hardness 50-60HRC, tempering hardness 46-48HRC.

Material 1.2343 Steel Equivalent

HS 2343 ESR-S steel, which is a 1.2343 steel equivalent material, belongs to electroslag remelting hot work die steel. It has uniform microstructure, excellent machinability and polishability, high toughness and high plasticity, high wear resistance, and overall hardening performance at high and low temperatures are both excellent. You can find 1.2343 steel equivalent to ASTM A681 H11 / ISO 4957 X37CrMoV5-1 / GB/T 1299 4Cr5MoSiV /JIS G4404SKD6 / FDAC from HITACHI

HS 2343 ESR-S (Material 1.2343 Equivalent) Heat Treatment

Soft Annealing:

820 to 860°C, after being heated through, cooling down to 600°C at a rate of 10°C/h with the furnace, then air-cooling, hardness max 230 HB.

Stress relief annealing: after rough machining, heating to 650℃ and holding for more than 2h, cooling down to 500℃ with the furnace, and then air cooling.

Quenching:

Preheating under a protective atmosphere to 500-600 ℃ for the first time, 820-860 ℃ for the second time, and finally heating to 900-1010 ℃

Quenching after being heated through at the quenching temperature for more than 30 minutes, hardness will be 50-55HRC.

Tempering:

Slowly heating to tempering temperature 560-600 °C after quenching, and it is recommended at least twice tempering. Achievable hardness: 42−50 HRC.

As a die steel supplier, we will do our best to meet all the needs of customers.

Contact : Dai Echo, 0510 86279732

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of HS 2343ESR-S Hot Work Die Steel Search in a category : Raw materials Search in a category : 2343esr, work, steel |

Tuesday, December 31, 2024

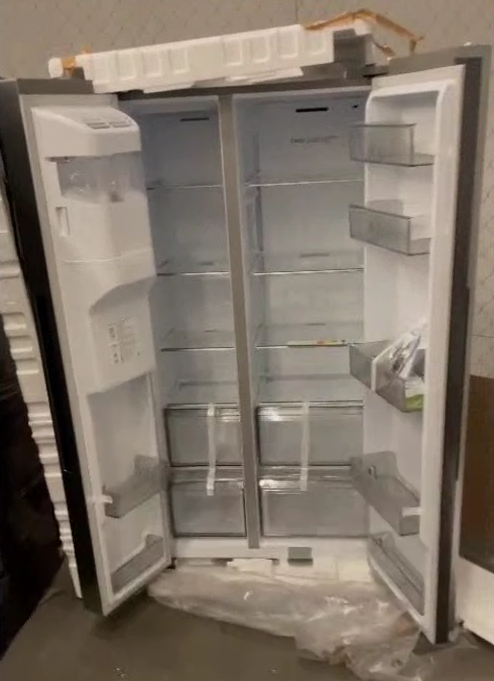

American Samsung Refrigerators

Quantity : 1000 - Price : 490,00 €

Exclusive Offer: Lot of 1000 American Samsung RS68CG882ES9 Refrigerators at Clearance Price! Seize this unique opportunity with a lot of 1000 American Samsung RS 68 CG 88 2E S9 refrigerators at an exceptional clearance price of €490 per unit. This high-end model is perfect for wholesalers looking to offer their customers a product that combines elegant design, advanced technology, and energy efficiency. Key features of the Samsung RS 68 CG 88 2E S9: - Large storage capacity ...

TRANSIDI

- 22440 - PLOUFRAGAN

- 02 30 96 63 26

- 33(0)603670505

Wednesday, June 17, 2015

Quantity : 100 - Price : $3,100.00

- MIMAKI APC-130 Apparel Cutter - 2 Tasks - 1 Machine APC-130 is based on Mimaki's extensive know-how within the cutting market and the company's highly appraised CG-series of cutting machines for the sign industry. Equipped with various functionality required by the apparel and...

PT DIGITAL MEDIA PRINTER

- john michael

- 1440 - Jakarta

- +62 (813) 1183 7053

Sunday, August 24, 2008

Price : fob

we are an italian off-shore firme operating in the textile sector with an italian experience of 25 years we offer a wide range of services: dyeing and finishing cloths for the fashion market. we meet our client 's high expectation by delivering the best service at the compétitif price...