|

|||||||||||||||||||||||

|

Raw materials

SiSiB® PC1108 |

|

CAS No. |

13497 18 2 |

|

EINECS No. |

236-818-1 |

|

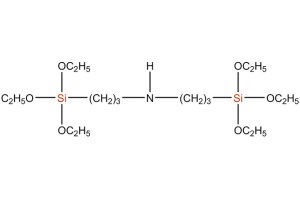

Formula |

C18H43NO6Si2 |

|

Molecular Weight |

425.71 |

|

Boiling Point |

160°C [0.6mmHg] |

|

Flash Point |

200°C |

|

|

|

|

Color and Appearance |

Yellowish clear liquid |

|

Density 25/25°C |

0.973 |

|

Refractive Index |

1.429 [25°C] |

|

Min. Purity |

95.0% |

Application

SiSiBSiSiB® PC1108 can be used in many applications, like:

Glass fiber/glass fabric composites: as size constituent or finish

Metal primers

Mineral fiber insulating materials, abrasives: as silicone additive to phenolic resin binders

Foundry resins: as additive to phenolic, furane and melamine resins

Sealants and adhesives: as primer or additive

Mineral-filled polymers (composites) or HFFR cables:

Pretreatment of fillers and pigments

Paints and coatings: improve adhesion to the substrate

SiSiB® PC1108 silane adhesion promoter can be used to improve:

Flexural strength, tensile strength, impact strength and modulus of elasticity

Moisture and corrosion resistance

Adhesion

Filler dispersion

Rheological behaviour: reduction in viscosity, newtonian behavior

Higher degree of filling

Packing and Storage

SiSiB® PC1108 is supplied in 25Kg steel pail, 180Kg steel drum or 900Kg IBC container.

In the unopened original container SiSiB® PC1108 has a shelf life of one year in a dry and cool place.

SiSiB SILICONES, established in 1989, is one of the leading silicone emulsion suppliers. We provide silicone in oil, Liquid Silicone Rubber, etc. Want to know more? Please contact us.

Contact : Amy Wu, 025 58599930

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of SiSiB® PC1108 Search in a category : Raw materials Search in a category : pc1108, sisib® |

Thursday, March 10, 2016

Before The Curing Appearance White Paste Tack Free Time ≤10 (min) Extrudability 5~11 (g/s,25℃) Cure Time 3~7(d) After the curing Relative Density 1.40~1.45 (g/cm3) Tensile Strength ≥2.5 (MPa) Break Elongation ≥500 (%) Shear Strength ≥2.0 (MPa) Hardness 45~55 (Shore...)

Guangzhou Usilicone Chemical Technology Co.,Ltd

- 523220 - Guangzhou

- +086 0769 88888312

Tuesday, February 03, 2026

Product Details Basic Info. Model NO.: YTC-61000 Type: Ink Jet Embossing Structure: Rotary Letterpress Structure: Satellite Application: Flexible Packaging Printing Automatic Grade: Automatic Printing Speed: 150m/mim Product Name: 6 Color Flexo Printing Machine Doctor Blade: Chamber...

Lisheng Printing & Packaging Machinery Co.,Ltd.

- 325409 - Wenzhou,Zhejiang

- +15 0 58 36 36 68

Tuesday, February 03, 2026

Composite Insulating Foam Cement Panel As a new type of insulated, non-ignitable and durable inorganic wall material with features of high strength, light weight, heat preservation, insulation and low water absorption, fire prevention and weather-proof, this product is the most...

http//:www.chinasingular.com

- 221000 - Xuzhou,Jiangsu

- 0086 180 2059 5192