Equipment goods

Efficient complete cassava starch processing plant cassava starch processing machine

Cassava processing plant cassava starch production line from CHINA DOING

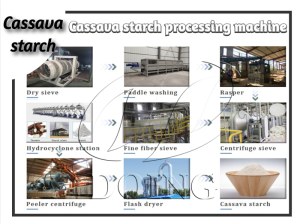

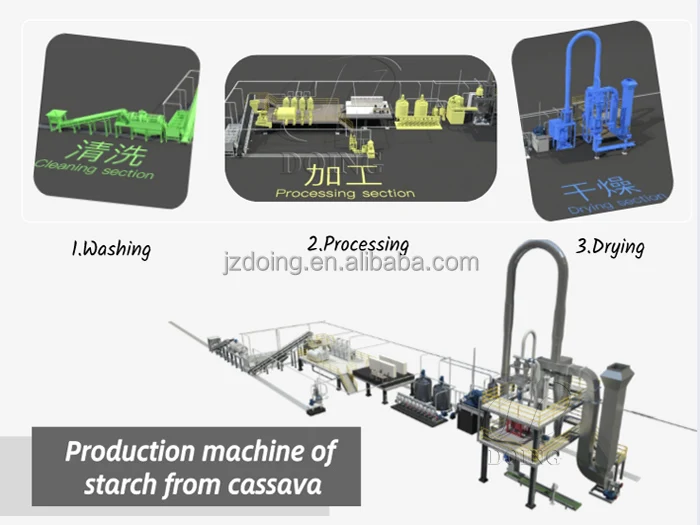

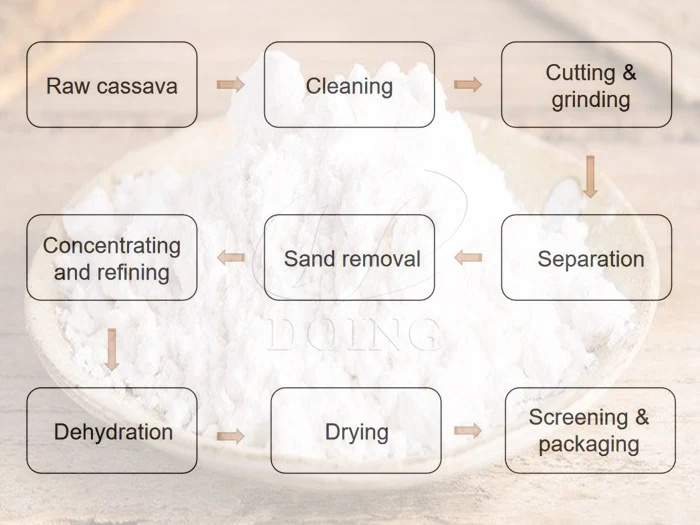

Fresh cassava tubers are often used as raw material for starch production. In our design, cassava starch is extracted by physical separation. The procedures are: raw material cleaning and washing, cutting and crushing of cleaned cassava, separating of different contents from starch slurry, concentration of starch slurry, dehydration and drying.

Flowchart of cassava starch production

Cassava processing plant cassava starch production line from CHINA DOING

Main cassava starch machines in production line

Cassava processing plant cassava starch production line from CHINA DOING

Pre-treatment of raw materials:

After raw cassava tubers are harvested from field, firstly they are cleaned and washed, in case that impurities go into further production and lower quality of finished product.

Dry sieve (cleaning)

Cassava processing plant cassava starch production line from CHINA DOING

Paddle washer (washing)

Cassava processing plant cassava starch production line from CHINA DOING

Processing section:

Cleaned cassava tubers are crushed to make starch released as much as possible. In the crushing section, normally it's divided into two steps, firstly cassava tubers are cut into small pieces, and secondly small cassava pieces are crushed completely to get cassava mash. In the cassava mash, it contains fiber, protein, fats, starch, water etc. To get purified starch, we need to separate all other contents. Normally solid impurities like fibers and tiny sands are preferentially removed, and then liquid impurities like protein and cell liquid are separated. After all above procedures are finished, we can get refined starch milk.

Cutting machine (cutting)

Cassava processing plant cassava starch production line from CHINA DOING

Rasper (crushing)

Cassava processing plant cassava starch production line from CHINA DOING

Cenrifuge sieve (fiber separating)

Cassava processing plant cassava starch production line from CHINA DOING

Hydrocyclone station (protein separating)

Cassava processing plant cassava starch production line from CHINA DOING

Drying section

After get refined starch slurry, the next is to remove extra water and get dried starch powder as output product. Firstly dehydration machine can convert starch milk into wet powder with moisture around 40%, and then flash drying machine dry it into powder with moisture 12-14%.

Peeler centrifuge (dewatering)

Cassava processing plant cassava starch production line from CHINA DOING

Flash dryer (drying)

Cassava processing plant cassava starch production line from CHINA DOING

Starch sifter (sieving)

Cassava processing plant cassava starch production line from CHINA DOING

Automatic packaging machine

Location : Room 1408, 14th Floor, Building 9, No.133 Yaozhai Road, Jinshui District, Zhengzhou City, Henan Province, China, 450000 Zhengzhou City,

Contact : Company DOING, 0086 135 2661 5783

Registered since 24 April 2020

Good deal: buying from seller

Visit our guide for a secure transaction! Under no circumstances Algomtl can be held responsible for the content of the ads published. Only the sellers and buyers responsability is involved in case of dispute. We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

Wednesday, February 17, 2016

Price : 15/USD/KG

Currently, we are exporting dried sea cucumber products as ball sea cucumber, white teat sea cucumber, flower teat sea cucumber, green sea cucumber, white sand sea cucumber& to countries as singapore, china, japan, malaysia, indonesia & europe... to be used as a cheers food...

- 50000 - CHIANG MAI

- +66 9 56 19 49 81

Tuesday, February 17, 2026

Waterproof Terry Cloth Mattress Protectors (PU Laminated Terry Mattress Covers) Waterproof and Breathable Terry cloth with PU membrane 80%cotton+20%polyester 170-180 gsm (can be arranged regarding customer needs) Protects mattress against all kinds of liquid spillage Durable stretched...

Tuesday, August 25, 2015

Quantity : non limité - Price : mini

Reliable Company looking partners in europe to export products mainly from Poland and other countries Eastern and Central Europe. We have contacts with european manufacturers so we are able to find all brands products at more competitive prices. At the same time we are guaranteeing...

- 42-510 - Tuliszow

- +48 7 30 88 19 53

|