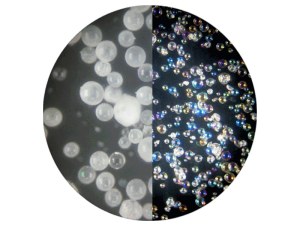

The high-performance hollow glass microspheres, a kind of ultra-light inorganic non-metallic powder with hollow "ball-bearing" shapes, have been developed into a new type of high-performance lightweight material and widely applied in recent years. It will be the main direction for new-type compound materials in the future. Its true density is 0.20-0.60 g/cm3; particle size is 2-120μm;

Hollow Glass Beads

The high-performance hollow glass microspheres, a kind of ultra-light inorganic non-metallic powder with hollow "ball-bearing" shapes, have been developed into a new type of high-performance lightweight material and widely applied in recent years. It will be the main direction for new-type compound materials in the future. Its true density is 0.20-0.60 g/cm3; particle size is 2-120μm;

Get Bulk Glass Beads Products Price List

Application of Hollow Glass Beads

Hollow glass beads for sale can be used as filler in paint, rubber, plastics, FRP, artificial stone, putty, exploitation of oil and gas and other materials.

The high-performance hollow glass microspheres are alternatives to conventional fillers and additives such as silica, calcium carbonate, talc, clay, etc., for many demanding applications. These low-density particles are used in a wide range of industries to reduce part weight, lower costs and enhance product properties.

The unique spherical shape of hollow glass microspheres offers a number of important benefits, including higher filler loading, lower viscosity/improved flow and reduced shrinkage and warpage. It also helps the hollow glass microspheres blend readily into compounds and makes them adaptable to a variety of production processes including spraying, casting, and molding.

The chemically stable soda-lime-borosilicate glass composition of hollow glass beads provides excellent water resistance to create more stable emulsions. They are also non-combustible and nonporous, so they do not absorb resin. And, their low alkalinity gives hollow glass microspheres compatibility with most resins, stable viscosity and long shelf life.

Storage and Handling of Hollow Glass Microspheres

To help ensure ease of storage and handling while maintaining free-flowing properties, hollow glass microspheres paint have been made from a chemically stable glass and are packaged in a heavy-duty polyethylene bag within a cardboard container. Minimum storage conditions should be unopened cartons in an unheated warehouse.

Under high humidity conditions with an ambient temperature cycling over a wide range, moisture can be drawn into the bag as the temperature drops and the air contracts. The result may be moisture condensation within the bag. Extended exposure to these conditions may result in the "caking" of the hollow glass microspheres to various degrees. To minimize the potential for "caking" and prolong the storage life, the following suggestions are made:

1. Carefully re-tie open bags after use.

2. If the polyethylene bag is punctured during shipping or handling, use this bag as soon as possible, patch the hole, or insert the contents into an undamaged bag.

3. During humid summer months, store in the driest, coolest space available.

4. If good storage conditions are unavailable, carry a minimum inventory, and process on a first in/first-out basis.

Choose TenRoads as your reliable hollow glass beads suppliers here!

Location : Builiding 27-1-1222 huijingxuan, Guangyang district,Langfang,Hebei,China, 065000 Hebei,

Contact : Lu Tracy , +86 15127621881