Good machinability titanium alloy round bar is made in china

Product Description:

Product name : Good machinability titanium alloy round bar is made in china

Standard : ASTM B348, ASTM F136/F67

Metrial : Pure titanium and titanium alloy

Technique : Forged, Rolled

Grade : GR1 GR2 GR5 GR7 GR9 GR12

Shape : Round bar, Square bar, Flat bar

Supply state : Annealing (M), Processing state (R), Cold machining (Y)

OD(outside diameter) : 6.35-114.3mm

L(Length) : Max 6000mm

Product Tolerance : H6, H7, H9, H11 etc.

Product Application:

Titanium bar is widely used in the field of oil drill pipe, oil exploration, oil drilling platform, vacuum coating, Equipment shaft processing, standard parts processing, non-standard parts processing, gas drilling equipment, such as high pressure resistance, wear resistance, corrosion resistance.

Physical Properties:

The advantageous Physical Properties of pure titanium are as follows:

1. Light weight [Specific gravity](60% of specific gravity of steel and about 1.7 times that of aluminum)

2. Low thermal expansion [Hermal expansion coefficent](ne-half that of 18-8 stainless steel and one-third that of aluminum)

3. Low hear conductivity [Heat conductivity](nearly the same as 18-8 stainless steel)

4. Low electric conductivity [Electric conductivity](about 3% of copper)

5. High flexibility [Longitudinal elastic modulus](one-half of iron or stainless steel and the same as copper)

6. Non-magnetism [Magnetic permeability](non-magnetic material; magnetic permeability = 1.0001)

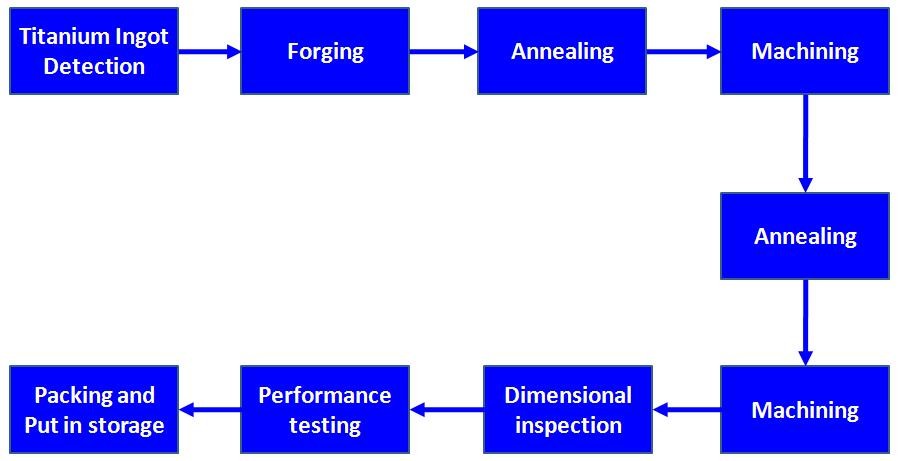

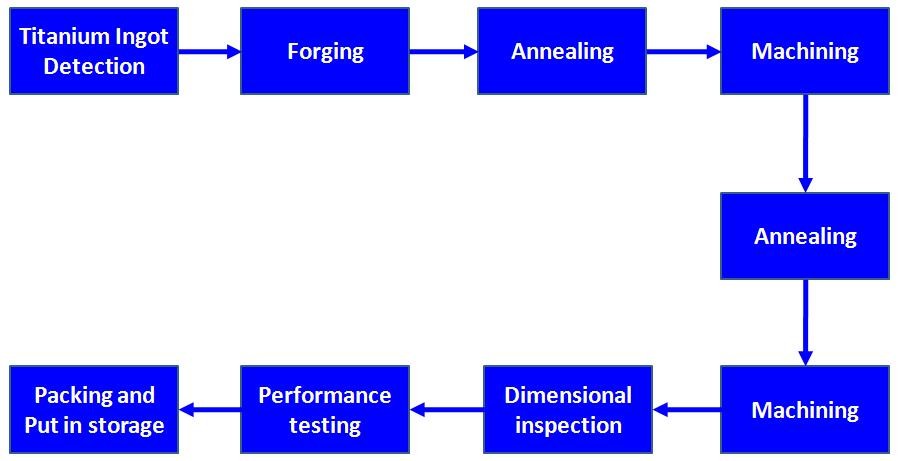

Titanium Bar Forged Production process:

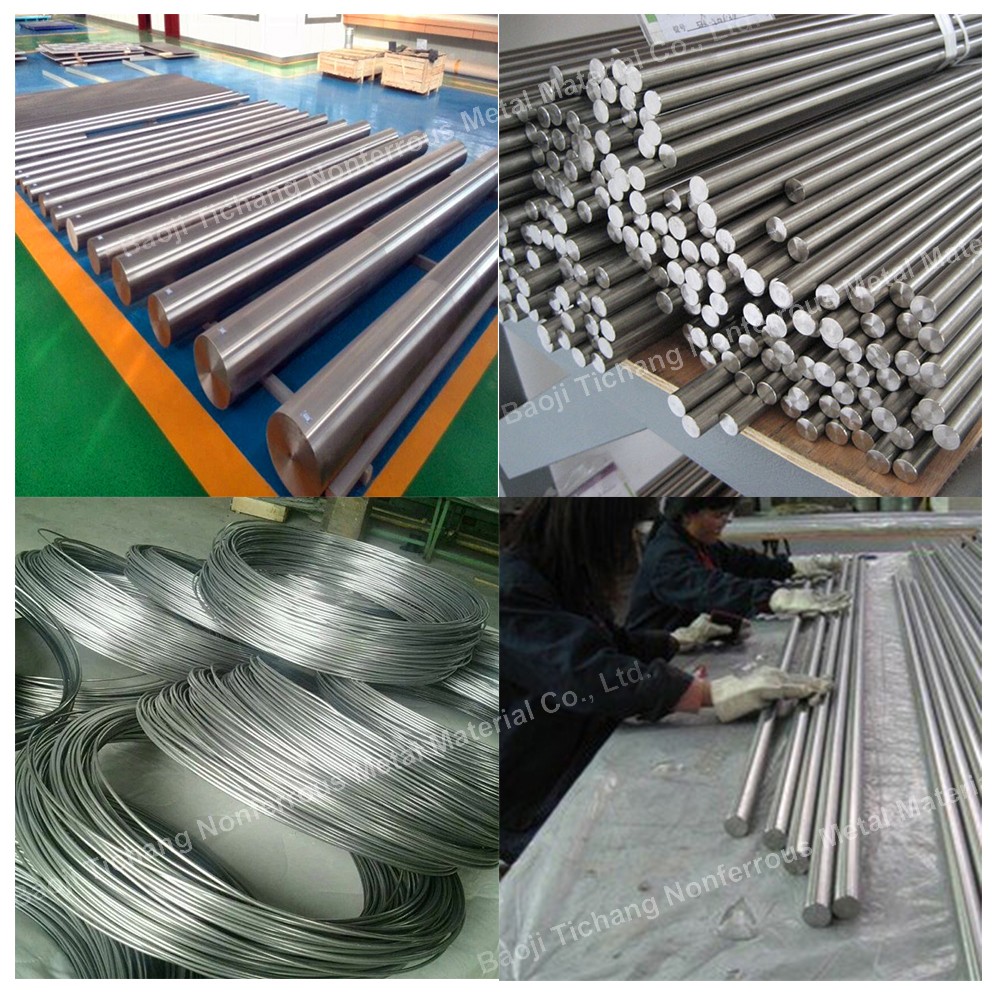

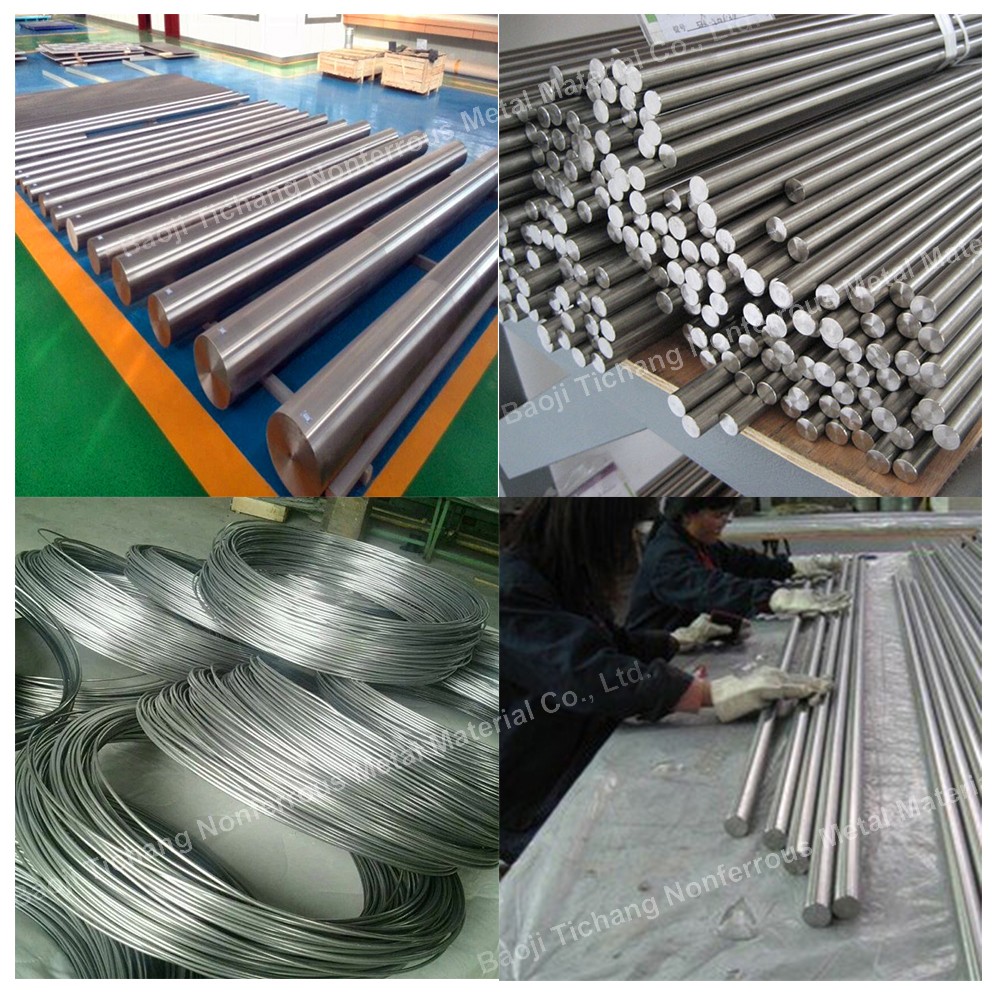

Product Show:

Company Introduction:

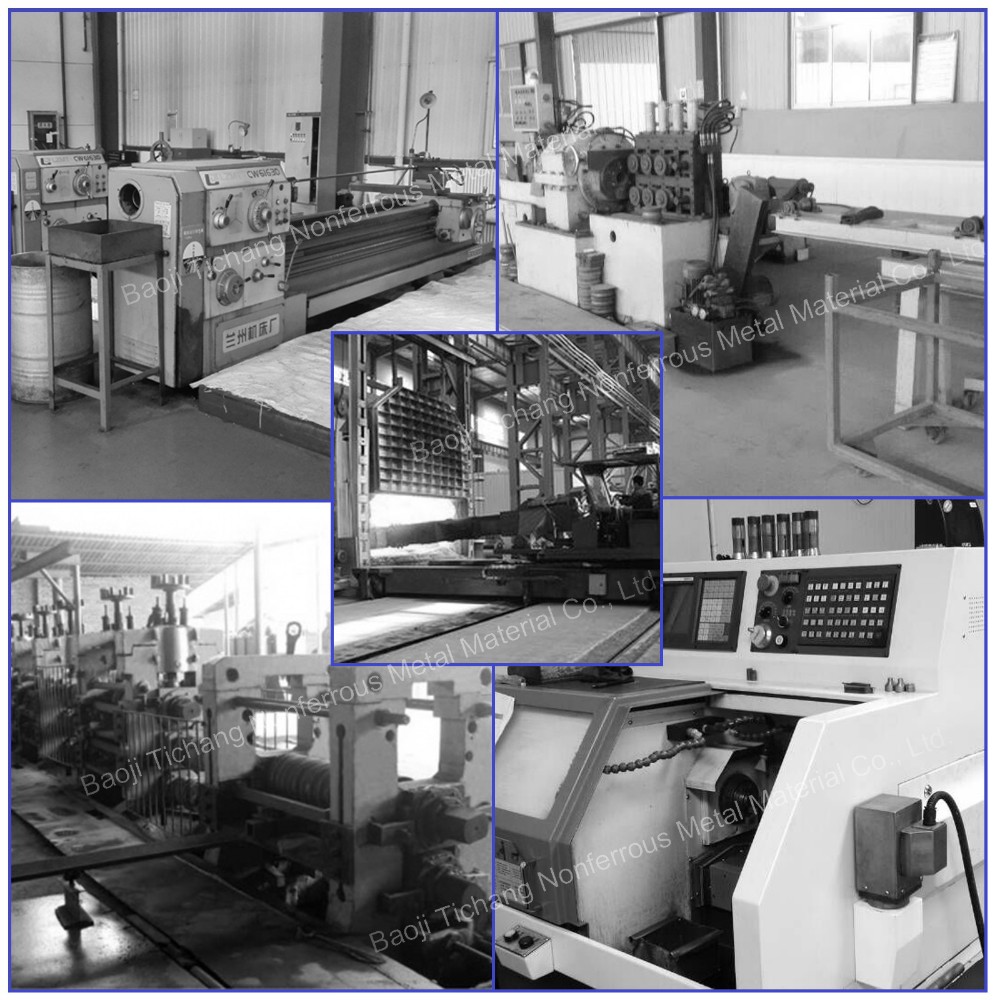

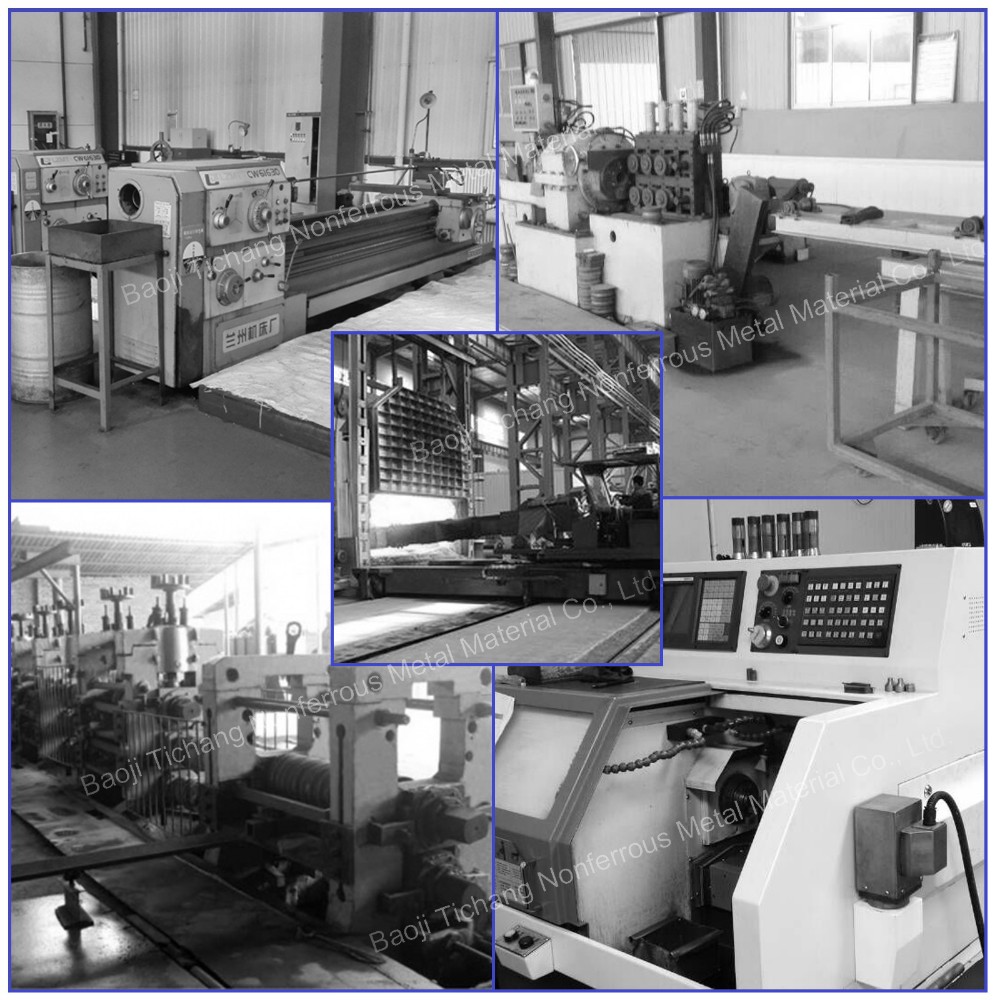

Baoji Tichang Nonferrous Metal Materials Co., Ltd is the medium enterprise which annual sales revenue reaches approximately 16 millions RMB with over 20 employees. Our company has advanced production technology, perfect testing, and product quality stable.

The specification of titanium bar and titanium alloy bar which we produce as follow: OD 6mm~200mm, Length(max) 6000mm.

Grade: GR1, GR2, GR5, GR7, GR9, GR12.

Standard: ASTM B348, ASTM F136F67.

Production methods: Forfing machining, Hot Rolling machining.

Production Process : Forging , Rotary Forging, Extruding, Rolling, Drawing

Production methods using forging machinery processing, hot rolling machining.

The products of our company including titanium bar, gr1 titanium bar, gr2 titanium bar, gr5 titanium alloy bar, gr7 titanium alloy bar, gr9 titanium alloy bar, gr10 titanium alloy bar, gr12 titanium alloy bar, titanium alloy bars for titanium alloy petroleum drill pipe, titanium alloy rod for titanium alloy stirring shaft, titanium standard pars, titanium non-standard parts.

Welcome to contact us for information or quotation!

Our Servces:

-

You will have your reply as quickly as possible within 10 working hours

-

We provide free sample

-

After the contract taking effect, we arrange production as soon as possible.

-

Guarantee Quality and Quantity.

-

There are preferential policies for long-term customers.

-

Customized service is available. Your demand is our offering standard

-

Quality guarantee for each item from our company is established.

Our Certifications:

Packing & Shipping:

FAQ:

Q1: Can we obtain the free sample?

A1: Sure certainly! We can provide the free sample completely if you pay the fare.

Q2: What is the advantage of your company?

A2: First of all, Our company has the quick delivery speed. What's more, the production of our company produce is various. Finally, we can

provide you a favorable price

Q3: How do you ensure the quality of the product?

A3: All products have passed by mechanics, chemistry, ultrasonic testing, radiographic testing, penetra tion detection, water pressure

testing and other professional three parties testing.

Q4: Are you a manufacturer or a trading company?

A4: We are professional and reliable manufacturer which specialized in titanium alloy forgings, titaniu m alloy bars, titanium alloy tubes,

titanium alloy sheet, titanium flange, all kinks of titanium alloy special-shaped parts, and titani um alloy standard parts.

Location : xuguang Industrial Park maying town high-tech zoneBaoji, Shaanxi, China, 721000 maying,

Contact : xin wang, +86 0917 3267086