|

|

|

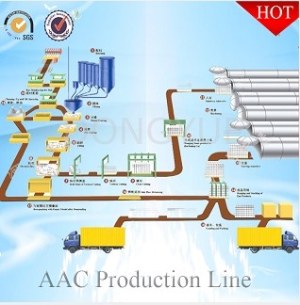

Equipment goods

Aerated concrete panel production line

|

|

This page is about importers and exporters of Aerated concrete panel production line Search in a category : Equipment goods Search in a category : concrete, aerated, panel, production |

Friday, January 01, 2021

Quantity : 100 - Price : 1,00 €

Grapeseed Oil Grapeseed oil is extracted from the seeds of grapes. It is an essential by-product of winemaking industry. This oil originated from France, Italy and Switzerland and now is easily available in the US as well. The grapeseed oil has numerous cooking uses as it has a...

ARGANisme Cosmetics S.A.R.L

- 40100 - Marrakech

- +212 651 925 398

Friday, May 24, 2024

Overview of Ti Gr1 Titanium Plate Yesheng Ti Gr1 Titanium Plate is a high-quality, commercially pure titanium plate made from grade 1 titanium. Ti Gr1 Titanium Plate Manufacturer is a popular choice because of its excellent strength, low weight, and good corrosion resistance, making...

Baoji Yesheng Titanium Industry Co.,LTD

- yesheng

- 721013 - baoji

- 0917 3906666

- +8615289358824

Tuesday, September 05, 2023

Quantity : 1 kg - Price : 5 EURO

Nila powder offers a range of benefits for the body's skin, from gentle exfoliation to soothing, as well as controlling excess sebum and improving skin texture. It also possesses anti-inflammatory qualities and helps lighten dark spots and areas of the body. In combination, nila powder...

BioProGreen

- bioprogreen

- 40100 - Marrakech - Tensift - Al Haouz

- +212524355671

- +212522023136

- +212661635894