|

|

|

B2B Services

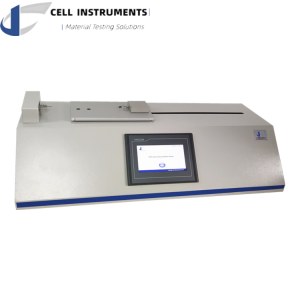

FPT-01 Friction and Peel Tester |

|

This page is about importers and exporters of FPT-01 Friction and Peel Tester Search in a category : B2B Services Search in a category : friction, tester , peel |

Friday, December 15, 2017

OEM PART NO DESCRİPİTİON 66072 Crown Wheel and Pinion FOR CARRARO 13X30 66941 Crown Wheel and Pinion 15x37 2277448 CATERPİLLAR AİR FİLTER OUTER 2277449 CATERPİLLAR AİR FİLTER İNNER 01/117901 FAN BELT 01/124403 FAN BELT 01/124404 02/100073 Oil Filter Canister Type, MEDİUM MODEL 02/100284...

ANAC MAKINA CO LTD STI

- 34800 - İSTANBUL

- +905069691531

- +9005069691531

Friday, October 09, 2015

Quantity : MOQ 24T

CAMEL RACE FEED Complete food flaked in addition to volume ration for camel sport in intense and medium work. Amount of 0.5 - 1.5 kg feed per 100 Kg of weight, depending on the age, size and activity of the camel. Allocate at least 3 daily rations, in addition to good forage and...

Agrofood Ganados

- 30410 - Murcia

- +34 9 68 10 66 28

- +34 6 72 36 35 29

Thursday, June 25, 2015

Quantity : Piece - Price : US $ 0.00058 - 0.007

Introduction These lids are made using thin sheets of food grade aluminum foil that are procured from the reliable vendors of the market. The foil lids are coated with PS laquor and are used to seal the PS cups to prevent spillage or leaks. Size customized Future 1) non-poisonous...

Jiangsu WoYuan Packing Co., Ltd.

- 224500 - Binhai

- 051584878588