The slewing drive is a full-cycle rotary reduction transmission mechanism integrated with a driving power source. The slewing bearing is used as a transmission follower and a mechanism attachment member, and an active member and a driving source are attached to one of the inner and outer rings of the slewing ring. And the casing, and the other ring is regarded as both the transmission follower and the connecting base of the driven working part, so that the slewing bearing itself is a feature of the full-circle rotary connecting member, and the driving power source and the main transmission are efficiently configured. The part makes it a general-purpose reduction transmission mechanism that integrates the functions of rotation, deceleration and drive, while having a simple structure and convenient manufacture and maintenance.

VE Vertically-Mounted Slewing Drive

The VE Series slewing drive gearbox is a vertical mounted design for low-speed (<1 RPM) outdoor applications. Its special structure effectively simplifies the complex structure design of the EPC bracket and r... </span>

SE Helical Tooth Slewing Drive

The SE Series Slew drive adopts enveloping worm gearing, more contact and higher torque. It can fit light duty, low speed and multiple precision options

WE Curved Gear Tooth Slewing Drive

The WE Series Slew drive adopts curved gear teeth which leads to more contact and higher torque.Its special processed gear prevents gear weary and adhesion. And it fits for heavy duty and medium appli...

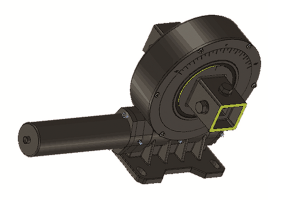

Heavy Duty Vehicle Series

The double-drive Heavy duty vehicle series can achieve 2 times the tooth contact on the single drive base, which makes it can produce nearly double the output torque in the same volume and installatio...

Precision PE Series

When you want the accuracy of the drive to be controlled between 0.05 and 0.15 degrees, there is no doubt that the precision type has a unique advantage in the high-end transmission field.Precision PE...

According to the form of the variable speed transmission of the slewing drive, it can be divided into a tooth type slewing drive and a worm gear type slewing drive, inheriting the respective characteristics of the gear drive and the worm gear slewing drive, and the two slewing drives can be adapted to medium and high speed and low speed applications respectively. In terms of carrying capacity, the worm-and-worm type performs better than the gear type, and its load carrying capacity, deformation resistance and transmission rigidity are further improved when using an envelope worm drive, but the efficiency of the worm-gear type slewing drive is Inferior to the toothed rotary drive. According to the openness of the slewing drive transmission mechanism, the slewing drive can be divided into open type and closed type. Generally, the open structure is mostly used in applications where the environment is too harsh, the maintenance and maintenance cycle is short, and the open structure is more convenient for the machine. Inspection, maintenance and maintenance are also easier to replace. Closed structures provide a longer maintenance lifecycle where environmental conditions do not change much and are below the level of environmental pollution below medium.

As the slewing drive manufacturers, Fuyong is one of the China leading producers of slewing ring drives and bearings. With a wide range of dimensions and designs, our worm slew drives and slewing ring are popular around the world. The slew drives and slewing bearing widely used in engineering machinery, coal mining machinery, fire equipment, industrial robots, photovoltaic power trackers, aviation and military defense. We have 18 independent intellectual property rights patents, and has passed ISO9000: 2008 quality management system certification and EU export CE certification, professional production, excellent quality.

Location : No.4, 1669 North Section of Huolishan Road, Cihu High Tech Zone, Anhui, China , 243000 Ma'anshan City,

Contact : Jacob Huang , +86 0555 3508865