The big irregular workpieces blasting and painting job has been widely completed by sand blasting rooms and painting rooms, cause of this of kind parts have all kinds of shape, it is very hard to arrangement the blasting turbines to automatically blast cleaning the big workpieces at all angles. it will be a big waste of electricity and blasting media.

Different shape of workpieces have different blasting angles, the automatically wheel blasting machines has not yet reached to the automatic level that blast cleaning different shape workpieces at a different angle.

Another difficult work is the transportation of different workpieces at a different weight, it will be a big cost waste of transportation system if we designed the whole system according to the biggest workpiece.

Take all these uncertain factors into consideration, the blast rooms and paint rooms are the best choices for the end-user.

The blast booth and paint booth can be arranged in parallel or serial, it depends on the customer' shop actual conditions to design, or according to the customer' workpiece moving direction and sequence.

Our company are blast booth manufacturers and we have sandblasting booth for sale.

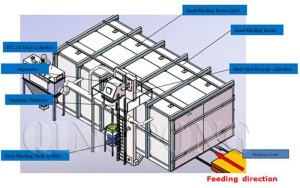

Sand blast cleaning room components

Blasting body

Sandblasting system

Abrasive reclaim system

Dust collector system

Workpiece conveying system

Electric control system

Lighting system

QINGGONG Blast abrasive media reclaim floors are a critical component of the abrasive blasting process. A highly efficient shot blasting room will save your operation time and labor expenses. This adds to your business's bottom line. An effective blast media reclaim system reduces costs by allowing for recycling of your abrasive media materials. Re-use of abrasive media reduces material purchase expenses as well as cutting of material disposal costs. As an added benefit, abrasive media reclaim systems allow for automation of blast media recovery, saving additional man-hours. An abrasive media reclaim system from QINGGONG will provide your business with maximum ROI from your abrasive blast system. QINGGONG offers a variety of reclaim floor designs and room configurations. We design blast room facilities uniquely tailored to meet the economic and production concerns of our customers.

Partial Reclaim System

sweep-chute floor The sweep-chute floor delivers the economic and environmental benefits of media recycling at a modest cost.

Single Screw or Scraper Partial Reclaim System

The most economical floor design available. The system contains screw conveyor or crapper conveyor, heavy-duty screw belt and bucket elevator,air-wash separator, perforated plate rotary drum separator and oversized abrasive storage hopper with a caged man ladder and handrail. This can be expanded to an "H","U", or full floor reclaim system and is best suited for low to medium production levels.

“H”-Shaped Partial Reclaim System

Adds two longitudinal conveyors along each sidewall of the blast room allowing the abrasive delivered from the blasting nozzle, which is either blown or rebounded off the workpiece, to strike the side walls and fall into the conveyors, automatically reclaiming approximately 60-90 percent of the blast media. The reclaiming abrasive on the floor is pushed into the screw or scraper conveyors assemblies at the end of the work shift. The “H” shaped floor design is typically used in a “flow-through” room configuration where heavy workpieces and/or material handling devices can drive into the room. This is best suited for medium to high production.

“U”-Shape Partial Reclaim System

Adds two longitudinal screw or scraper conveyors assemblies along each wall of the blast room and positions the cross screw or scraper conveyors along the back wall of the blast room. This allows the abrasive delivered from blasting nozzle, which is either blown or rebounded off the workpiece, to strike the sidewalls and back wall of the blast room and fall into the reclaim system, A "U"-shaped floor design will automatically reclaim 60-90 percent of the blast media. The remaining abrasive on the floor is pushed into the metered shed plate screw assemblies at the end of the work shift, The "U"-shaped floor design is typically used in an "in-out" room configuration where heavy workpieces and/or material handling devices can drive into the room. This is best suited for medium to high production

A major benefit of this type of system is that it only requires a shallow concrete foundation. This can create substantial savings for the customer in comparison to other types of recovery systems. It also avoids the issue created by digging foundations in an area that have high water table levels. The full-floor reclaim design requires that the material handling of the workpiece be intricately designed into the configuration of the room. Material handling of the workpiece includes a work car/track system, an overhead monorail crane, an overhead bridge crane or guide rail work cars, heavy-duty floor grating and support steel sized to allow a forklift to drive onto the reclaimed floor. This design can be used with any room configuration and is best.

As one of the most professional shot blasting equipment manufacturers in China, QINGGONG MACHINERY's activity is the design, manufacture, sales of automatic shot blasting machine, sandblasting room and punching machine and over more than 40 years of experience. RFQ today!

Location : No 377, Langyatai S Rd, Huangdao District, Qingdao City, China, 266400 Shandong,

Contact : Sara Sara Li, 0532 82121566