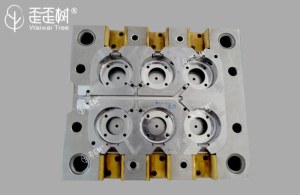

BMC/SMC Moulding Description:

We mainly use SMC injection molding and pressure molding as the methods. When designing the flow channel and parting surface, we think that the cavity pressure should be as small as possible, especially some small ribs, as well as the smooth exhaust, the discharge position, shape, and material flow direction, which would all be fully considered. And the active exhaust must be complete with an overflow. We guarantee the appearance and strength. With the Vacuuming structure, the mold temperature balance is consistent as the appearance and strength of the product shall be guaranteed as well.

SMC/BMC Mould Features:

high insulation, chemical resistance, high fire resistance, good water resistance, accurate size, stable working performance, light weight, high strength, acid and alkali resistance, waterproof, moisture-proof, low energy consumption, no waste, no need to clean the mold cavity, mold The temperature is stable, the temperature difference is small, the breakage is short, poor appearance is less, and the efficiency is high.

About BMC/SMC Moulding:

The basic process of the compression molding process is to place a certain amount of the pre-treated molding material into a preheating compression mold, and apply a higher pressure to fill the mold cavity with the molding material. Under the predetermined temperature conditions, the molding material is gradually solidified in the cavity, and then the SMC product is taken out from the stamper, and the necessary auxiliary processing is performed to obtain the final product.

The pressing process of the composite molded product is a process of solidifying into a product in a cavity after the binder is loaded or heated under the condition that the curing agent is present or heated. Molding temperature, molding pressure and mold exhaust, temperature balance, and mold structure all affect the quality of SMC products. It is necessary to determine the best solution under the consideration of various influencing factors.

BMC is the initial abbreviation of English Bulk Molding Compound, and the Chinese name is a group molding compound. Pre-mixed into a paste by unsaturated polyester resin, low shrinkage/low profile additive, initiator, internal mold release agent, mineral filler, etc., and then added thickener, colorant, etc., with different lengths of glass fiber, in special Stirring in the kettle is carried out to carry out a thickening process, which finally forms a dough-like intermediate material which can be used for molding and injection molding.

The BMC injection molding process basically follows the same rules as the injection mold. However, SMC and BMC molds also have different characteristics from injection molds, such as flow path, exhaust, heating, cavity pressure and balance, parting structure, mold steel used and precision, shrinkage and injection molds. Differently, the BMC mold is molded at a high temperature, and the plastic mold is molded at a normal temperature.

SMC and BMC molds require heating rather than cooling systems. The temperature of the mold is usually between 130 and 160. It is very important to keep the temperature of the mold and the exhaust gas when designing the mold. The mold is easier to fill, the product is not easy to be deformed, and the surface is better. Commonly used heating systems are steam, oil and electric heating rods.

Vacuum assisted systems for BMC and SMC molds: Products with Class A surfaces are usually vacuum-assisted, and the internal cavity and vacuum insulation of the mold are very important. The mold must have a sensor and a vacuum system to measure the mold temperature and pressure vacuum. Production SMC and BMC molds must guarantee high quality, long life and economy. Aobang Technology Co., Ltd.'s years of experience in the production of SMC and BMC molds and proficiency in machine, mold, material and process can ensure the maximum benefit of customers.

Zhejiang Aobang Technology Co., Ltd. is one of the most professional sheet molding compound manufacturers in China, and we hope to gain recognition and support from our customers and to develop mutual cooperation.

Location : No.62,zhidailang,sha village,luoshe town, deqing,huzhou city, zhengjiang, China., 313218 huzhou,

Contact : Li Coffee, +86 15657163173