|

|

|

Equipment goods

WL-FS-100K Stainless Steel Pipe Straight Seam Welding Machine price |

|

This page is about importers and exporters of WL-FS-100K Stainless Steel Pipe Straight Seam Welding Machine price Search in a category : Equipment goods Search in a category : seam, stainless, 100k, steel, welding, pipe, straight |

Tuesday, February 11, 2020

Quantity : 100 - Price : 1,00 €

We are Zafer Yangın Engineering Industry and Trade Limited Company; , from Turkey ,specillized in fire safety , We design the fire protection systems planned to be established in the facilities with our expert engineer staff. We provide consultancy services for determining the risk...

ZAFER YANGİN

- 34764 - iSTANBUL

- +90 216 479 99 12

- +90 0530 470 92 13

Thursday, June 16, 2022

Quantity : 100

Logitech G PRO Gaming. Utilisation recommandée: Jouer. Type de produit: casque, Style de casque portable: Arceau, Couleur du produit: Noir. Technologie de connectivité: Avec fil, Connecteur USB: USB Type-A, Longueur de câble: 2 m. Couplage auriculaire: Circum-aural, Fréquence des écouteurs...

MaKant Europe GmbH & Co. KG

- 60386 - Frankfurt am Main

- +49 (69) 9 150 750 14

Friday, July 28, 2023

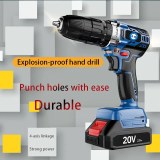

Quantity : 1000 - Price : $980.00/ piece10 pie

argument Marque GYPEX Modèle YBDK-120/12VC Origine Chine continentale Moteur moteur sans balai Source de courant courant continu Tension 12V Vitesse changement de vitesse sans fin Type de mandrin Mandrin rapide Durée de vie à vide 120min Engrenage de vitesse...

Foshan Pengchang Construction Machinery Co., LTD

- GYPEX

- 510700 - Guangzhou china

- +13 0 60 69 94 15