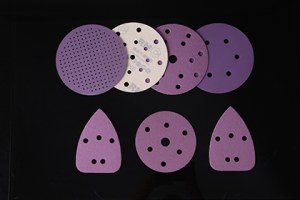

Abrasive discs are circular tools made of abrasive materials attached to a base, typically made of fiberglass, plastic, or metal. Abrasive discs are used for a variety of tasks, such as grinding, sanding, polishing, and cutting. Abrasive sanding discs can be attached to power tools, such as angle grinders, bench grinders, and sanders, and come in a variety of sizes and shapes to suit different applications and materials.

As one of the best abrasive disc manufacturers, RMC abrasives disc could supply all the different application products. Lacquer, steel, wood, plastic, auto repair, furniture, wall, floor, marble, and so on.

Why Choose RMC Abrasive Disc?

RMC brand abrasive disc could supply long grinding life, perfect polishing surface, Super anti-clogging, and static. High tear resistance, flexible. High-cost performance. Fast cutting efficiency.

What is Abrasive Disc?

Abrasive discs are carriers used to coat or embed abrasives, enabling the abrasive grains to play a cutting role, and at the same time, they are also shaping tools for grinding surfaces. Rotating discs, cylinders, cones, flat plates, oil stones, thin plates, , rings, and specially shaped grinding discs can be used as grinding tools.

An abrasive disc is a type of cutting or grinding tool that is used for removing material from a surface. They typically consist of a circular disk made of abrasive grains, such as aluminum oxide or silicon carbide, that are held together by a bonding material. The abrasive grains are designed to remove material from the surface through a process known as abrasion.

Abrasive discs come in a variety of sizes and grits, which determine the coarseness of the abrasive grains. Coarser grits are used for heavy-duty grinding and cutting, while finer grits are used for finishing and polishing. Abrasive discs can be used with a variety of power tools, including angle grinders, bench grinders, and sanders.

It's important to choose the right type of abrasive disc for the task at hand, as different abrasive discs are designed for specific materials and applications. For example, some abrasive discs are designed specifically for use on metal surfaces, while others are designed for use on wood, stone, or composites. Additionally, it's important to use abrasive discs safely and follow the manufacturer's instructions to avoid accidents and damage to the workpiece.

How to Use Abrasive Discs

First, you should choose the right abrasive disc types, make sure you select the right sanding disc for your task. Consider the type of material you are sanding and the desired finish. And then, when you use a disc abrasive, you should consider some useful points below.

Sanding discs and backing pads have a tendency to get clogged with debris which can ruin your project, or even worse. Ensuring that you have a clean disc at all times will increase both the speed and quality of your work.

Angle grinders and other tools come with guards for a reason. Make sure to always reinstall the guard before turning on your equipment. The guard should be installed at all times unless you're using the grinder for its intended purposes. If your tool does not include a guard, install one. Use a dust collection system to minimize the amount of dust and debris generated during sanding.

As one of the most professional wholesale abrasive suppliers, we provide abrasives china, 9 sanding disc 80 grit,9 sanding disc 40 grit, 9 inch sanding discs for metal, 9 inch sanding discs 60 grit, 9 inch abrasive disc, 7 sanding disc pad, 7 sanding disc 80 grit, 7 inch sanding disc 16 grit, etc. For more information, please feel free to contact us!

Location : No. 61, Qinfen Road, Xinbei District, Changzhou, Jiangsu Province, China., 213125 jiangsu,

Contact : Lio Zhao, +13 5 61 68 53 88