|

|

|

B2B Services

PLATING

|

|

This page is about importers and exporters of PLATING Search in a category : B2B Services Search in a category : plating |

Wednesday, April 15, 2015

Quantity : Inquiry - Price : USD 0.8-1.5/piecs

Dimensions : 156mm x 156mm ± 0.5mm. Thickness (Si): 180μm ± 20μm / 200μm ± 20μm. Front : Silver bus bars Silicon nitride anti-reflection coating. Back : Silver bus bars Full-surface aluminum BSF. Location : 5F,No.2.Sec.4.JhongyangRd,TuchengCity.Ta ipei County 236,Taiwan R.O.C,...

Taiwan

- 23678 - New Taiwan City

- +886 2 22691686

Tuesday, March 03, 2026

- Film Feuille, Tube et semi-tube de haute, moyenne et basse densité. Polyéthylène de matières pures ou recyclable. Transparent noir, blanc, translucide ou opaque. -Film imprimé -Film thermo-rétractable -Film pour emballage automatique ou manuel -Feuille pour rebords ou pour...

EXPLATEC SL

- 08210 - Barbera del Valles

- +34 6 47 06 21 76

Wednesday, June 27, 2012

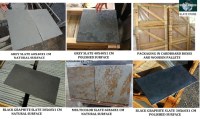

Quantity : min 1 cont

La pizarra de Brasil Tamaños estándar: 30x30, 40x20, 30x60, 40x40, 50x50, 60x40, 60x60, 60x90 y 80x80, 90x90 cm, de cualquier tamaño, previa solicitud (incluidas las tablillas, escaleras, marcos de ventanas, etc) También Disponible en diferentes...

MINAS SLATE (Minas Mundo Ltda)

- minasslate

- 35669000 - papagaios

- 553732740261

- 553791169143