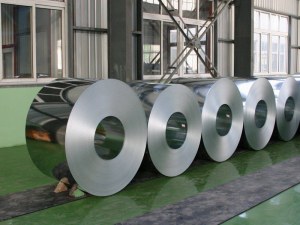

China Aluminum Sheet Supplier Henan Lichen aluminum Co., LTD is a professional hot rolled aluminum plate, 1000~6000 series aluminum sheet factory, and a professional China aluminum company. We have different types of aluminum coil for sale, including 1060 aluminum coil, 3003 aluminum coil, 5052 aluminum coil, etc. So far, Lichenalu has earned more than 20 years of experience in China aluminum coil manufacturing. As one of the most experienced China aluminum coil suppliers, Lichenalu is confident in providing high-quality aluminum coil products to our customers. Welcome to wholesale 5052 aluminum coil, 5754 aluminum coil, and other types of aluminum coil from Lichen.

Aluminum Coil Types

1060 Aluminum Coil

Available in ASTM-B221. Aluminum 6061 square bar is ideal for applications such as engineering or structural applications for a wide variety of components. Heat Treatable Excellent Corrosion Resistance Good Workability Good Machinability

3003 Aluminum Coil

3003 aluminum coil is a commonly used Al-Mn antirust alloy. Similarly, 3003 aluminum coil is also a non-heat-treated alloy, and its mechanical properties can be improved by conventional cold processing.

5052 Aluminum Coil

The 5052 aluminum coil is an Al-Mg alloy and also contains a small amount of elements such as manganese, chromium, and zinc. With the exception of a small part of the manganese component in the alloy. We have different 5052 Aluminum Coil types as follows:

5754 Aluminum Coil

5754 aluminum coil is a typical 5 series Al-Mg anti-rust alloy. Because it contains the main alloy component Mg, it has excellent corrosion resistance, rust resistance, and high fatigue strength.

6061 Aluminum Coil

The 6061 aluminum coil is a high quality aluminum alloy produced by heat treatment prestretching process, with a series of advantages such as excellent processing performance and good weldability.

1050 Aluminum Coil

1050 aluminum coil belongs to commercially pure wrought 1000 series alloy family with a purity of 99.5% Al. So, 1050 aluminum coil properties show excellent ductility, plasticity, corrosion resistance. We have 1050 aluminum coil types as follows:

Differences Between Aluminum Bar 6061 and Aluminum Bar 6063

Aluminum Bar 6063

Aluminum 6063 is one of the most popular aluminum extrusion alloys on the market. Often referred to as architectural aluminum, 6063 is often used within architectural applications. This medium strength alloy is often used for applications such as railings, window frames, door frames, roofs, and more.

For more detailed information about the differences between aluminum alloys 6061 and 6063, please check out our blog post.

Aluminum Bar 6061

Aluminum bar 6061 is a structural aluminum alloy that maintains extremely good mechanical properties. 6061 is considered a wrought alloy, as opposed to a casting alloy, which means that it can be extruded, rolled, or forged into a variety of shapes.

Aluminum bar 6061 is highly suitable for applications such as building products, electrical products, piping, and recreational products.

Aluminum Coil Advantages

Aluminum Bar 6061

Aluminum bar 6061 is a structural aluminum alloy that maintains extremely good mechanical properties. 6061 is considered a wrought alloy, as opposed to a casting alloy, which means that it can be extruded, rolled, or forged into a variety of shapes.

Aluminum bar 6061 is highly suitable for applications such as building products, electrical products, piping, and recreational products.

Aluminum Bar 6063

Aluminum 6063 is one of the most popular aluminum extrusion alloys on the market. Often referred to as architectural aluminum, 6063 is often used within architectural applications. This medium strength alloy is often used for applications such as railings, window frames, door frames, roofs, and more.

For more detailed information about the differences between aluminum alloys 6061 and 6063, please check out our blog post.

Aluminum Coil Applications

Aluminum bar is produced through an extrusion process and is elongated using dies. Aluminum bar can be produced into a variety of different shapes and can be used for many different industrial applications. Aluminum bar has many different uses and industrial applications due to its light weight, corrosion resistance, and excellent machinability. Aluminum bar continues to be the choice metal for many different industrial applications including:

Medical Assembly

Aircraft Construction

Structural components

Commercial Transportation

How is Aluminum Bar Manufactured?

Aluminum bar is most commonly manufactured through the process of extrusion. In extrusion, an aluminum bar is manufactured by pushing the material through a die that is under pressure. As the aluminum is pushed through the pressure-filled die, it is processed into the producer's desired shape, which is either square, rectangle, hex, or round.

Location : 54th Floor, Twin Tower, Greenland Center, Intersection of Dongfeng South Road, Zhengdong New District, Zhengzhou City, 471003 Dongfeng South Road,

Contact : deng mary , 0379 62630557