The Role of Using Equipment Maintenance Management Software

Ⅰ. What is equipped enterprise asset management?

Equipment maintenance management software is a very general management information system. Using equip enterprise asset management can effectively manage equipment resources and maintain the normal operation of equipment, thereby improving work efficiency. For example: after the transformation of various production enterprises to automation, machines replaced the previous labor, which increased the production efficiency of the enterprise and reduced the management cost, but the number of machines and equipment in the enterprise increased. Generally, a manufacturer with 100 sets of equipment needs 1 to 2 maintenance personnel Engineers to conduct spot checks, maintenance, repairs, spare parts management, etc. on various types of equipment.

Ⅱ. Application of equipment maintenance management software

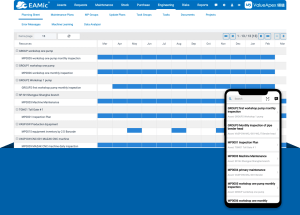

With equipment maintenance management software, any situation of each piece of equipment can be centrally managed, including:

1. The equipment manager sets the inspection and maintenance cycle of various equipment, and the maintenance personnel conducts regular inspections and maintenance.

2. If the inspection personnel find any problems, they will report to the maintenance personnel through the software with one click, and the maintenance personnel will accept the order within 1 second.

3. After the maintenance is completed, describe the maintenance, evaluate the equipment, and see the health of the equipment at a glance.

4. Managers can check the operation status of enterprise equipment in real-time.

5. View equipment maintenance records in real-time.

6. The management personnel can check the work results of each maintenance employee in real-time and have real data reference for the workload and enthusiasm of each employee.

Ⅲ. What are the general functions of enterprise equipment maintenance management software?

1. Equipment asset management: that is, the registration and entry of equipment, and the registration and recording of various basic information of equipment into the system, which is very convenient for query and statistics;

2. Fault report and repair: fault registration and record, you can quickly report for repair by scanning the QR code with your mobile phone;

3. Maintenance work order management: For a fault that has been reported for repair, it can be approved for repair or not; if it is repaired, who will be assigned to repair it; after the repair is completed, whether the repair result is qualified can be rejected or passed;

4. Maintenance: Arrange and assign tasks in advance for tasks that require cleaning, lubrication, and maintenance of equipment;

5. Point inspection management: For the tasks that need to be inspected every day, set them in advance;

6. Planned maintenance: In order to ensure better operation of the equipment, sometimes it is necessary to carry out shutdown maintenance in a planned way, or even dismantle and repair the equipment components. The interval between such maintenance tasks is generally very long;

7. Equipment knowledge base: management of equipment operation manuals, maintenance manuals, etc., equipment failure and corresponding maintenance plan management; other functions include spare parts management, equipment visualization management, data statistical analysis, equipment operation status monitoring, etc.

In order to better manage enterprise equipment, more and more enterprise units have begun to introduce equipment maintenance management software to improve the efficiency of equipment management.

We custom software for a wide range of industries including oil and gas asset management software, food inventory management system, chemical inventory management software, manufacturing maintenance software, spare parts management software, automotive parts inventory management systems, machine maintenance software, asset management software for electronics, etc.

Location : No. 90 Zijin Rd., New Disrict, 215011 Suzhou,

Contact : We Good, 0512 6239 7998