1. What is equipment management software?

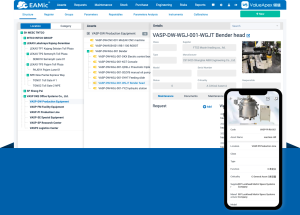

Equipment management software refers to management software for enterprise devices. With the expansion of the production scale of enterprises and the acceleration of informatization, the equipment data is becoming more and more complex, and the data volume is increasing. It is no longer enough to rely solely on manpower to manage the equipment of an entire enterprise. And then a number of enterprise management solutions came into being. Equipment management software is an equipment information management system that is used daily in the equipment management department of the enterprise. It can support and optimize the equipment management process, improve the efficiency of equipment maintenance, and ensure the stable operation of the equipment, and can enable enterprise managers to grasp the operation dynamics of equipment efficiently and timely, so as to ensure the normal operation of production.

Equipment management software realizes data sharing, reduces duplication of work, and improves efficiency and accuracy. On the basis of high degree of data sharing, based on the basic data of equipment management work, a dynamic management system for equipment work is established. The equipment management software combines basic management of assets and equipment, technical management and economic management, and forms comprehensive statistical analysis reports based on systematic data information to scientifically manage equipment. The equipment management software formulates reasonable equipment maintenance standards and point inspection standards to provide scientific basis for equipment maintenance and early failure management.

2. The application value of equipment management software

The purpose of enterprise application equipment management software is to establish a history file of the entire life cycle of equipment, improve equipment operation efficiency, and reduce equipment maintenance costs, so as to realize system management of equipment throughout the life cycle, and at the same time provide for the deployment of equipment after the end of individual projects Utilization, refurbishment, etc. provide information basis that can be inquired, traced, and referred to.

In addition, in combination with emergency maintenance reports, maintenance reports, spare parts used, etc., informationization and integration are realized, and finally, one-to-one correspondence between equipment shutdowns and equipment maintenance reports is realized, and equipment emergency maintenance reports and shutdown records are accumulated. After analyzing such massive data, Form equipment preventive maintenance plans and emergency maintenance instructions, and establish intelligent "emergency-analysis summary-preventive maintenance" such benign equipment usage specifications.

At the same time, the consumption of spare parts by the equipment management software can intelligently predict the life and consumption of spare parts from massive data according to the model, and reduce the downtime caused by damage to spare parts and the cost of spare parts inventory. At the same time, the way of repairing is changed, and the method of scanning the code is convenient and fast, making the repairing more timely and efficient.

You may be interested in our spare parts management software.

We custom software for a wide range of industries including oil and gas asset management software, food inventory management system, chemical inventory management software, manufacturing maintenance software, spare parts management software, automotive parts inventory management systems, machine maintenance software, asset management software for electronics, etc. Contact EAMic® - the best EAM Software & Systems for 2022.

Location : No. 90 Zijin Rd., New Disrict, 215011 Suzhou,

Contact : We Good, 0512 6239 7998