Pharmaceutical Water Systems

Water is the most widely used process raw material in the pharmaceutical industry, which is used as the composition, solvent and diluent of drugs. Pharmaceutical water is mainly divided into two categories:

Purified water: it is pharmaceutical water prepared from raw water by distillation, ion exchange, reverse osmosis or other appropriate methods, and does not contain any additives.

Water for injection: It is the water obtained by taking purified water as raw water, distilling in a specially designed distiller, condensing and cooling. Sterile Water for Injection is the water prepared according to the injection production process.

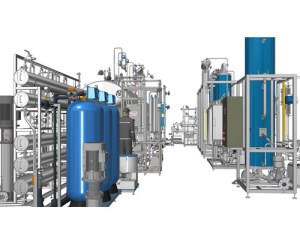

The purified water system in pharmaceutical is composed of water treatment equipment and transportation system. Through design, installation and confirmation, judge and evaluate whether the equipment meets the predetermined production capacity, water quality standard, capacity, flow rate, pressure, temperature, disinfection method, etc.

The operation and maintenance of water system in pharma company shall be monitored and managed according to the requirements of verification and documents. Ensure that the operating parameters of the system are within the range of operating parameters confirmed by the equipment.

TYPES OF BIOCELL PHARMACEUTICAL WATER SYSTEMS

Pharmaceutical Water Purification System

Water For Injection System (WFI)

Pure Steam Generation System(PS/CS)

Purified Water System(PW)

PW/WFI Storage & Distribution Systems

Pharma Water System Control & SCADA

Sanitary Heat Exchanger

Pharmaceutical Water Purification System

The pharmaceutical water system is composed of water treatment equipment and transportation system. Through design, installation and confirmation, judge and evaluate whether the equipment meets the predetermined production capacity, water quality standard, capacity, flow rate, pressure, temperature, disinfection method, etc.

Ultrapure Water System

Ultrapure water is produced by distillation, deionization, reverse osmosis technology or other appropriate supercritical fine technology. Now ultrapure water has been widely used in biology, medicine, industrial manufacturing and other fields. Ultrapure water system refers to the production system in which raw water and ultrapure water are completely produced. The conductivity of common tap water is less than 10-20 after being treated by the primary reverse osmosis system μ S/cm, permeate conductivity1-5 after secondary reverse osmosis system μ S/cm is even lower. The reverse osmosis system can be supplemented with ion exchange equipment or EDI equipment to prepare ultrapure water, making the resistivity as high as 18.25 megohm. cm.

GOOD DESIGN PRINCIPLES OF BIOCELL PHARMACEUTICAL WATER SYSTEM

01

Customization

Comprehensively understand the customer's actual needs for water preparation process, system configuration, etc., and customize the water system.

02

Cooperation

BIOCELL is a member of China Pharmaceutical Equipment Industry Association, and has long maintained technical exchanges and cooperation with many well-known domestic pharmaceutical enterprises.

03

Experienced

BIOCELL has a group of industry senior experts, professional designers and experienced project installers who have practiced in many application fields for many years, with an average working time of more than 10 years.

Location : Room 4423, building 01, No. 88, Zhujiang Road, Xuanwu District, Nanjing, 210008 Nanjing,

Contact : .com biocell, 025 83192994