|

|||||||||||||||||||||||||||||||||||||||||

|

B2B Services

FW INVERTING CENTRIFUGE

|

|

Item / Model |

FW-630 |

FW-800 |

FW-1000 |

FW-1300 |

|

Drum diameter (mm) |

630 |

800 |

1000 |

1300 |

|

Drum volume (L) |

70 |

120 |

200 |

350 |

|

Filter area (m2) |

0.56 |

0.85 |

1.26 |

2 |

|

Max. revolving Speed (r/min) |

1940 |

1600 |

1270 |

1000 |

|

Max. Separating factor (N) |

1325 |

1144 |

901 |

726 |

|

Weight of Machine (Kg) |

3600 |

4200 |

5500 |

6500 |

|

Outline Size (mm) (L×W×H) |

2970×1040×1650 |

3980×1450×1890 |

4990×1650×2560 |

5900×2050×3250 |

FW INVERTING CENTRIFUGE CHARACTERISTICS

1. Fully sealed structure design, reliable sealing, no pollution to materials

2. The shell can be completed and turned over for easy cleaning and inspection.

3. Discharge without scraper mechanical parts, no damage to grain crystal.

4. There is no material residue in the filter cloth, which is convenient for the separation of materials in the next batch.

5. Unmanned operation, automatic detection, and operation.

FW INVERTING FILTER CENTRIFUGE WORKING PRINCIPLE

After the start-up of the equipment, firstly judge whether the proximity switch of the motor end is effective or not. If not effective, the assist motor will work to seal the drum. After that, the assist motor will stop and the main motor start to run. After the drum reaches the set speed, the feeding valve will open and suspension will enter into the full-speed rotary drum filtration through the feeding pipe. Under centrifugal force, the solid of the suspension will be distributed evenly on the internal surface of the filter mesh and most of the liquid will pass through the small holes on the filter mesh and drum wall and be drained outside through the liquid outlet. After a long time operation, the thickness of the solid product inside the drum will keep gaining. When reaching the set time, the feeding valve will close automatically. (feeding time will be changed for different products and can be adjusted at first commissioning).

FW Performance and Use

FW series are inverting filter centrifuges with intermittent feeding and intermittent discharging.

Feeding, separating, washing, dehydration, and other operating procedures are completed under full speed; discharging is completed under the condition of deceleration, which avoids material contact with subject other than equipment, and can protect the operator and material from pollution as well.

The machine meets GMP specifications and is suitable for filtration and separation in pharmaceutical, food, and chemical industries.

FW Inverting Centrifuge Highlights

01.

FW inverting filter centrifuge with fully sealed structure design, reliable sealing, no pollution to materials.

02.

The shell of inverting filter centrifuge can be completed turned over for easy cleaning and inspection.

03.

Discharge without scraper mechanical parts, no damage to grain crystal.

04.

There is no material residue in the filter cloth, which is convenient to the separation of materials in the next batch.

05.

FW inverting centrifuge with unmanned operation, automatic detection and operation. FW inverting centrifuge meets GMP specifications and is suitable for filtration and separation in pharmaceutical, food and chemical industries.

As a professional industrial centrifuge manufacturer, Saideli provides industrial centrifugal dryer, solid solid separation equipment, solid liquid centrifugal separator and etc. Want to know more, contact us.

Contact : centrifuge saideli, 0086 523 84808886

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of FW INVERTING CENTRIFUGE Search in a category : B2B Services Search in a category : inverting, centrifuge |

Tuesday, February 03, 2026

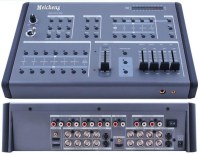

Applications : CMX-12 is a high definition digital AV Mixer, which is a simple type of HD/SD Video Mixer Editor to switch and effects. Each input BUS supports 6 inputs (2 x HDMI, 2 x Component, 2 x S-Video and Composite video) and also Background Color for special effect. The output...

Meicheng Audio Video Co., Ltd.

- meicheng

- 23511 - New Taipei City

- 886 2 82280311

Tuesday, February 03, 2026

Quantity : 500 - Price : USD0.5/pc

100 years American Technology China Excellent Manufacturing Partner of Fortune top 500 Leading Brand in T bolt hose clamp Ind T Bolt Hose Clamp KTBF156 1)Rated Ultimate Torque: Plated Steel Bolt & Nut: 90in.lbs. (min.)(10.2Nm)300 Series Stainless Bolt & Nut: 75in.lbs...

King Seal Fastener Technology(Anhui) Co., Ltd.

- 233010 - Bengbu

- 86 552 4193229

Thursday, June 10, 2010

SIAM-SUWAN-INTERNATIONAL-COMPANY-LTD is a French-Thai company established in Songkhla in the South of Thailand. It markets products directly from the big Thai suppliers, without intermediaries, and which offers you also services in French. Not gaseous RED-BULL in bottles glass of...

SIAM-SUWAN-INTERNATIONAL

- siam-suwan

- 90140 - SONGKHLA

- +33 6 14 48 52 24