|

|||||||||||||||||||||||||

|

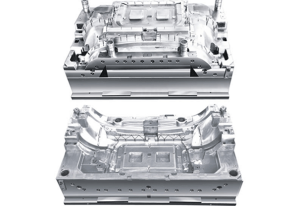

Equipment goods

Prototype Injection Mould

|

|||||||||||||||||||||||||

|

|

Prototype Mold |

Production Mold |

|

Objective |

I need to prove my original design at Packson. I need the best solution for price and design before production and get parts quickly within 10-15 days |

I have big volume production needs at Packson and need an open long-term running production mold. |

|

Best When |

1. Improving part design and provide solutions for the part making |

1. With finalized design and construction, what we need to focus is to reduce ineffective communication and create a personal solution with a more competitive price. |

|

Mold Cavities |

Normally single cavity |

Single and multi-cavities |

|

Mold Life |

Limited (guaranteed for at least 2,000 shots-5,000 shots) |

Unlimited |

|

Mold Storage |

Upon customer's decision. Some will be destroyed once they confirm the design |

Some will be shipped to the customer's molding company. Some will be left at Packson for long term running |

|

Quality Documentation |

A basic inspection like tolerance control and finishing control |

Full-spectrum inspection operating by CMM and all kinds of measuring equipment |

|

Shared Features |

Raw Material: Aluminum or Steel |

|

Process For Prototype Mold

There are many things that need to be considered such as the product design needs to be perfect and it has to achieve actual full functionality before they get into the market. If there is any failure for your products which means the part design is not fulfilled yet and we need to keep improving the design and finding a better solution. Therefore, prototype mold is the best way for us to prove some issues before you are able to take your products into the market. Here is the process for prototype mold, you will find out what prototype mold exactly is:

There are 4 simple steps for prototype mold:

Start with a plastic part design

Initial concept or design is always the essential and critical part of manufacturing.No matter what kind of product you create like an electronic device or medical device, making the design and design should be the first step.

You should make sure of the feasibility and functionality when it comes to plastic product design. Moreover, you have to consider the concept is doable or not. If the design fails then it would waste time. But never mind, we have a professional engineer team who will make assessments for your design and provide our suggestions to help make the design better.

Providing DFM(Design for Manufacturing) and processing solution

We will make DFM according to your part design and offer a processing solution at a competitive price. Normally we will choose a removable insert which takes by hand during production, this will help cut some costs. But this is only used for small batch production within 500 shots. We will also analyze the thickness, angle draft, injection point, etc during these steps for making sure everything is ok before we start processing.

Mold creation or 3D printing

Simple 3D printing is fully sufficient for simple and small quantity plastic products. Therefore the expensive test mold is not neccessary.3D printing is a very simple process without much explanation. For another processing, the way is mold creation. This is the most important process in plastic prototyping. We will process the mold according to the tooling design and we will choose the steel which is softer and easier to carve out. This will help to make mold quickly with a short lead time. Rapid processing is one of the obvious features of the prototype mold. Because we don't need to make it like production mold as long as it can be operated and good for proving the customer's part design.

Making the prototype plastic molding parts by injection machine

For prototype mold, the plastic parts also need to be molded by a plastic injection machine. The mold will be placed into the injection molding machine and then injected with the plastic prototype material. Later material will be cooled by the water lines to allow it to create a shape on the cavity. After the cooling process, the mold will be opened when pressure from the clamp is released. Finally, the part will be ejected from the machine.

Applications of Prototype Mold

There are many applications for prototype molds like automotive, medical. These applications will keep increasing because of the development of new procedures. Here are some of them:

The making of molds – different grades of steel even plastic resin can be made through prototype mold.

The making of cores – SLS application is the latest technology used in sand casting shapes and cores.

The electrodes for EDM, making of marking stamps are some of the applications of prototype molds. Most of the applicated industry at Packson is automotive and medical.

There are many benefits for the prototype molds. With the features of low cost, quick lead time, and effective processing way, it will allow you to bring your parts into the market faster. The most important advantage is low-cost processing because it can make market testing with low volume production.

If you want to know more kinds of medical plastic parts, please visit our website.

Contact : mould packson, 0086 769 87866635

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Prototype Injection Mould Search in a category : Equipment goods Search in a category : prototype, injection, mould |

Wednesday, January 29, 2014

Quantity : 100 - Price : 1,39 €

General Specs Type : Protection Case Pattern : Steve Jobs Pattern Function : Non-slip, dustproof and shockproof Compatibility : iPhone 4/4S Features 1, A protection case for Apple iPhone 4/4S, 9 pattern available. 2, Fits the contour of cellphone precisely. 3, Easy access to all buttons...

les saveurs SMD

- oasisnet

- h1s1l9 - montreal

- 514 424 2338

- 01 514 424 2338

Friday, December 12, 2014

Technische Daten: - 100% brandneu - Feine Verarbeitung, Modernes Aussehen und praktisches Design - Idealer und starker Schutz vor Staub, Kratzern - Freier Zugriff auf alle externen Knöpfe und Stecker - Genaue Löcher hat reserviert - Einfach einzusetzen - Kompatibel mit Samsung Galaxy Tab3 8...

365buy

- 3600 - Thun

- 07 62 07 63 81

Friday, March 11, 2016

Empresa de impresión y comunicación dinámica con sede en Dakar ofrece los siguientes servicios y productos: - Diseño de logotipos, folletos, folleto de ventas, folleto, bandera ... - Impresión en: camiseta, camisa de polo, gorra, tela, papel kraft, sobre lienzo ... - Bordado en...

CECIKA CORPORATE

- 00221 - Dakar

- 00221774825999