Online Particle Size Analyzer

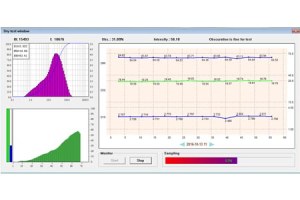

BT-Online1 online particle size measurement is an on-line particle size monitoring system for real-time particle size monitoring and control in powder manufacturing

industries. Driven by Standard Operation Procedure (SOP), the particle size monitor automatically samples, measures, recovers and processes data directly from the powder delivery pipeline, providing 24-hour particle size detection and control for a variety of dry powder production lines.Measurement: Particle size

Particle size range: 0.1 to 1000µm

Dispersion type: Dry

Technology: Laser diffraction

Features and Benefits

Measuring range: 0.1 - 1000 µm

Repeatability: ≤3% (GBRM D50)

Accuracy: ≤3% (GBRM D50)

SOP: Standard Operation Procedure

Detectors: 68 pieces

Test speed: ≤1 min

High-performance semiconductor laser with long lifespan

Automatic Alignment

Automatic Centering

Performance

1. Real-time Control System

As well as being able to continuously monitor particle size analysis of nanoparticles, the system also has a function for real-time feedback and control. The system will collect real-time size data and perform calculations against the particle size control limits. It automatically generates the feedback signal to the control center. This closed loop feedback control system will achieve better quality improvement, higher efficiency, reduce wastage and save energy.

2. Automatic Centering Guarantees perfect conditions of the optical system

By moving the laser detector center point to the focus point of the lens before each test, the automatic centering function guarantees perfect conditions of the optical system, therefore providing accurate and repeatable testing results.

3. Accuracy Calibration Maintain accurate datum lifetime

This function maintains operating parameters at consistent conditions, producing consistent and reproducible measurement across the board for all instruments, old and new.

4. Reliable Sampling System

Sample dispersion is achieved by accelerating the powder through a venturi. The "backflush" and tapered pipe design prevents blockage of the sampling tube, and keeps the residual powder clean, ensuring the accuracy and continuity of real-time testing.

Three different dispersion mechanisms can act upon the sample:

5. Versatile Functionality of the System

The system has power interruption protection and over-pressured protection functions. Under these abnormal operating conditions, it will initiate an automatic shutdown

sequence to protect the system from harm. The electrical and mechanical system of the BT-online1 has robust interference protections; it is ready for the haphazard nature of a production environment and an electromagnetic interference prone environment.

6. Contamination Prevention Optics System

Using the controlled principle of aerodynamics, we devised the double air-cushion lens protection system. The contamination prevention technology will form an invisible double air shield between the sample stream and the lens, eliminating the optics from contamination from sampling, as well as a dust-prone environment. With this technology, the ultimate goal of a long duration of sustainable operation, providing real-time, continuous particle size monitoring and control can be realized. Accuracy and continuous monitoring of the production data can be achieved.

Location : No.9, Ganquan Road, Jinquan Industrial Park, Dandong, Liaoning, China., 118009 Dandong,

Contact : Xu Spring , +15 1 41 55 76 96