|

|

|

Everything else / Bulk

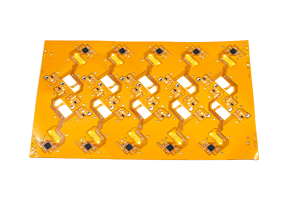

Flex PCB Assembly |

|

This page is about importers and exporters of Flex PCB Assembly Search in a category : Everything else / Bulk Search in a category : flex, assembly |

Friday, December 15, 2017

OEM PART NO DESCRİPİTİON 66072 Crown Wheel and Pinion FOR CARRARO 13X30 66941 Crown Wheel and Pinion 15x37 2277448 CATERPİLLAR AİR FİLTER OUTER 2277449 CATERPİLLAR AİR FİLTER İNNER 01/117901 FAN BELT 01/124403 FAN BELT 01/124404 02/100073 Oil Filter Canister Type, MEDİUM MODEL 02/100284...

ANAC MAKINA CO LTD STI

- 34800 - İSTANBUL

- +905069691531

- +9005069691531

Thursday, October 03, 2019

Price : 56 €/m²

modular metal building all sizes, temporary or permanent. Buildings in extensible and fully removable kit. main metal structure composed of profiles type "C" or "SIGMA" cold formed and galvanized secondary structure on coverage and facade perimeter composed of profiles like "Z" cold...

HADDOUCHE

- 33140 - CADAUJAC

- 06 72 47 36 41

- +33 6 72 47 36 41

Saturday, September 12, 2015

AES specializes in manufacturing battery disconnect switch for vehicle applications. The product include heavy duty battery cut-off switch, 2-4 position, 4 terminals battery disconnect switch, master battery disconnect switch with AFD, lockout lever battery disconnect switch, single...

Top Quality Auto Electric Products Co., Ltd.

- aesautoparts

- 70255 - Tainan

- +88 6 62 65 23 19