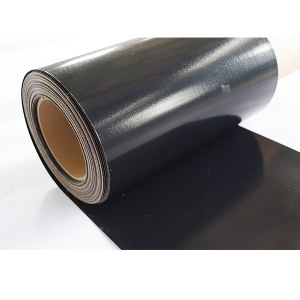

Anti Static PTFE fiberglass cloth is coated with specially formulated PTFE coating adding carbon additive to offer not only nonstick surface but also non-conductive and anti-static property.

The Details of Anti Static PTFE Coated Glass Fiber

Anti-static PTFE coated glass fiber is formulated with special black PTFE coating, adding carbon additive to make surface anti-static and non-conductive properties, in the meanwhile keep its common features include high heat and chemical corrosion resistance, unique nonstick smooth surface, and UV, IR and HF resistance. Application of the anti-static PTFE fabric includes making into a conveyor belt for fusing press machine, as release sheets and for heat sealing where the electrostatic charge would build. Anti-static PTFE coated fiberglass is designed for the electronic industry, static electricity attracts dust which will lead to contamination of integrated circuits and semiconductor components, anti-static PTFE coated fiberglass helps to eliminate static and increase the production rate of finished electronic products.

The Advantage of Anti Static PTFE Coated Glass Fiber

Superior smooth surface than normal material in the market

Excellent nonstick surface for quick release

Well Operational under temperature from -73-260 ℃(-100-500℉)

Non-conductive surface eliminate static build during operation

High strength and durability for longer time use

Max width available up to 2600mm

Superior tear strength and flexibility

Preventing electrostatic discharge inflammable explosive environment

Non-flammable

Low coefficient of friction, anti-aging

How to make joint for Anti Static PTFE Coated Glass Fabric Belt?

Mutiflon customizes the most suitable joints to fit customers' requests:

1. Overlap joint:

the most common joint type is overlap two ends of belt with about 25mm-50mm width lapped according to the belt length in vertical angle or an angle about 30°or 45°.

2. Alligator joint or called finger joint:

If customers wish thickness of joint part almost and same as other part, Mutiflon will punch two ends of belt in alligator type, then interlace them together with a piece of thin Kevlar fabric covered.

The Applications of Anti Static PTFE Coated Glass Fabric

Electric industry – Static electricity attracts dust which will cause contamination of integrated circuits and semiconductor components, anti-static PTFE glass fabric will help to dissipate static and improve rate of finished products.

Textile industry – Anti-static PTFE glass fabric in thickness of 0.25mm and 0.35mm is perfect to be made into fusing machine belt for some applications care about cost than tensile strength, because this fusing machine belt is cost effective than seamless belt

Paper making and printing industry – The electrostatic attraction will cause the paper to be rolled unevenly and cause register difference, this problem will be solved by using anti-static PTFE fabric.

MUTIFLON is a professional seamless belts manufacturer, we provide ptfe coated fiberglass fabric, black ptfe fiberglass cloth anti static ptfe fiberglass cloth, anti static coating for glass, ptfe antistatic liner, high temperature resistant cloth and etc. Want to buy Fusing Machine Belt, contact us.

Location : No.2 Junmin Road, Urban Industry Park, Taixing, Jiangsu, China, 225400 Jiangsu,

Contact : Ye Elina, +86 0523 87990007